Guarantee + Warranty

Patton stands behind all of our products with a 90 day, 100% money back guarantee and a full 24 month parts warranty. Click Here for full policy

Products

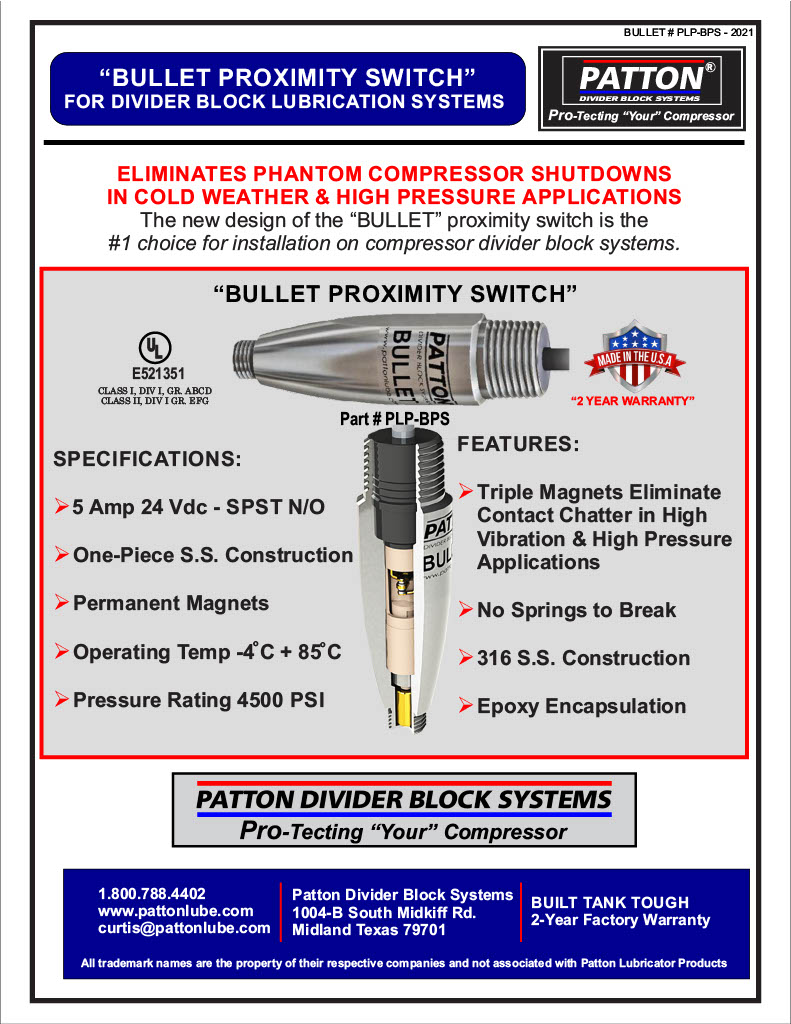

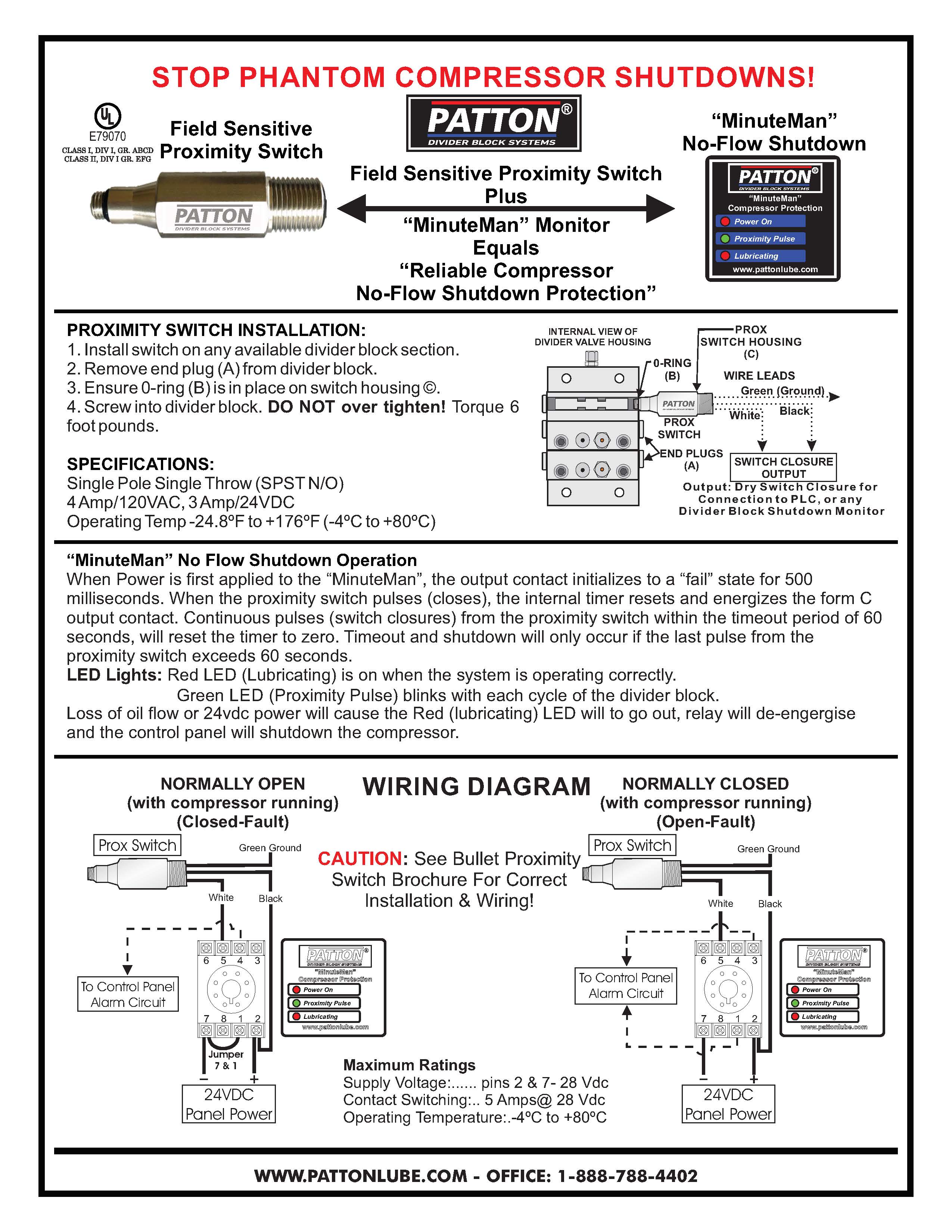

Proximity Switch

Field Sensitive "BULLET" Proximity Switch (Full PDF)

ELIMINATES PHANTOM COMPRESSOR SHUTDOWNS IN COLD WEATHER AND HIGH PRESSURE APPLICATIONS

The Problem:

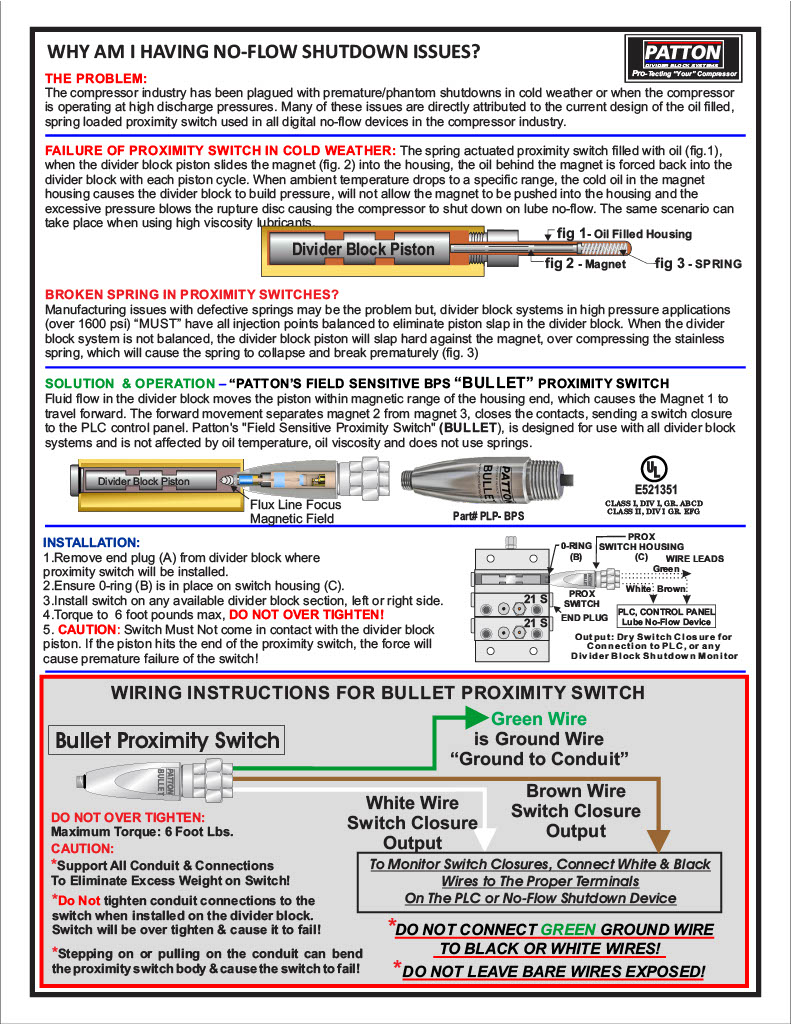

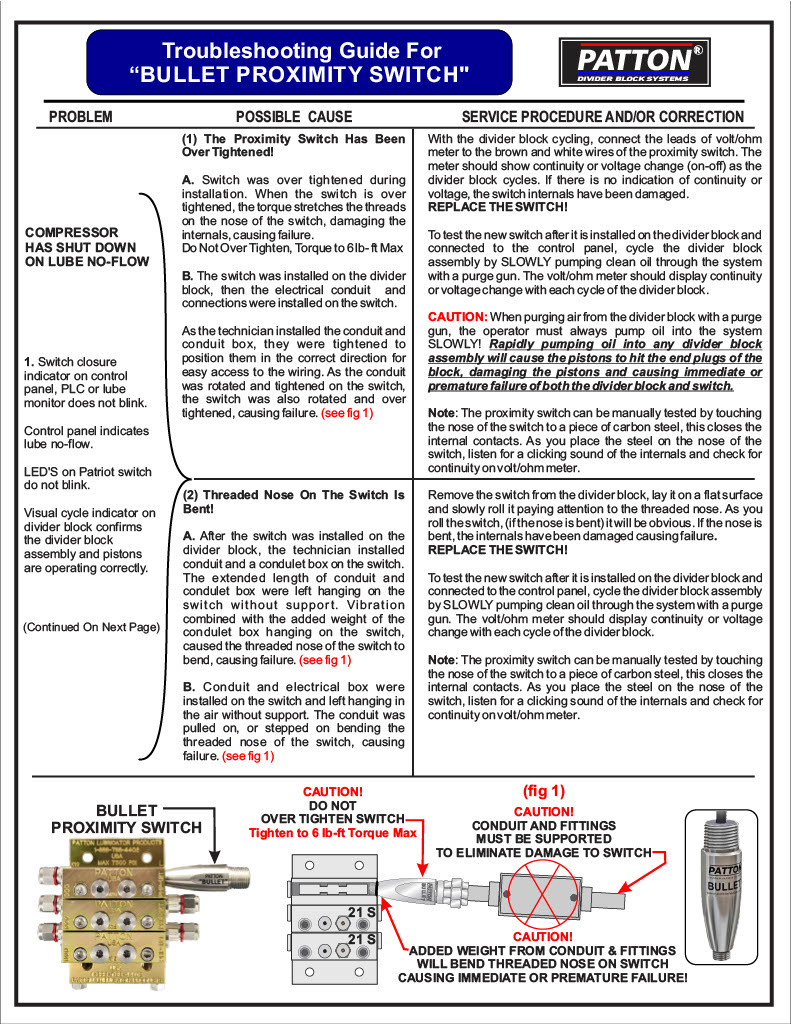

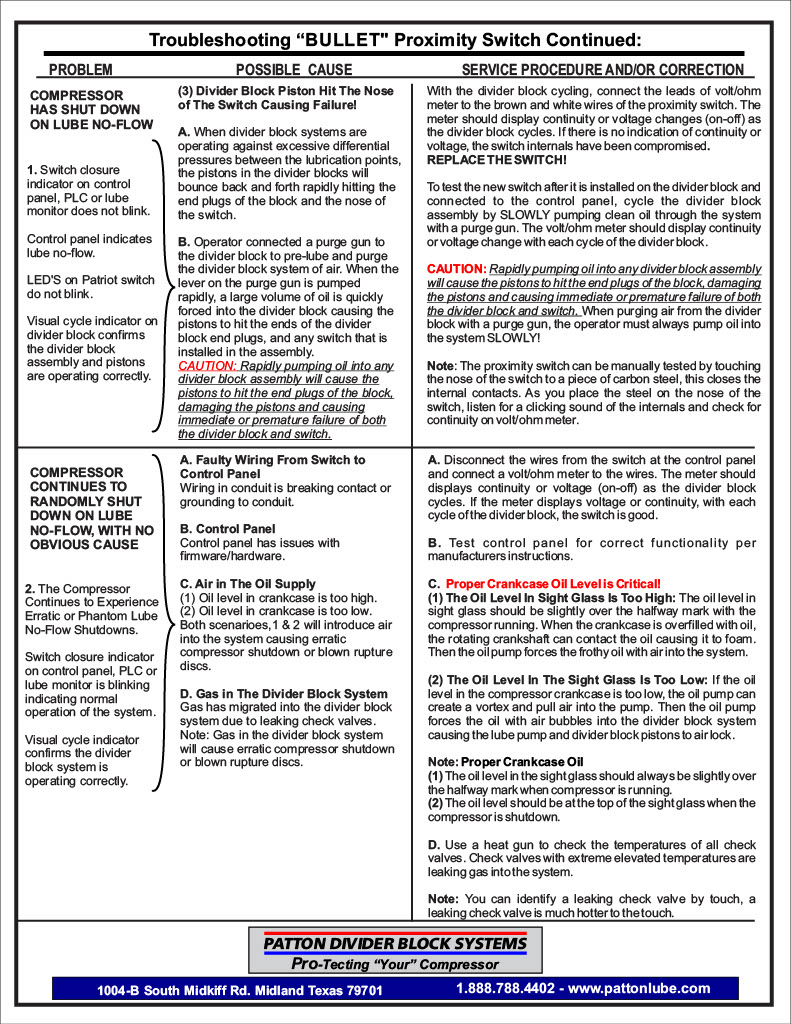

The compressor industry has been plagued with premature/phantom shutdowns in cold weather or when the compressor is operating at high discharge pressures. Many of these issues are directly attributed to the current design of the oil filled, spring loaded proximity switch used in all digital no-flow devices in the compressor industry.

The Cause:

The spring actuated proximity switch is filled with oil and when the divider block piston slides the magnet into the housing, the oil behind the magnet is forced back into the divider block with each piston cycle. When ambient temperature drops to a specific range, the cold oil in the magnet housing causes the divider block to build pressure and will not allow the magnet to be pushed into the housing. The excessive pressure blows the rupture disc causing the compressor to shut down on lube no-flow. The same scenario can take place when using high viscosity lubricants.

The Solution: PATTON’S FIELD SENSITIVE BPS BULLET PROXIMITY SWITCH

Fluid flow in the divider block moves the piston within magnetic range of the housing end, which causes the Magnet 1 to travel forward. The forward movement separates magnet 2 from magnet 3, closes the contacts, sending a switch closure to the PLC control panel. Patton's "Field Sensitive Proximity Switch" (BULLET), is designed for use with all divider block systems and is not affected by oil temperature, oil viscosity and does not use springs.

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

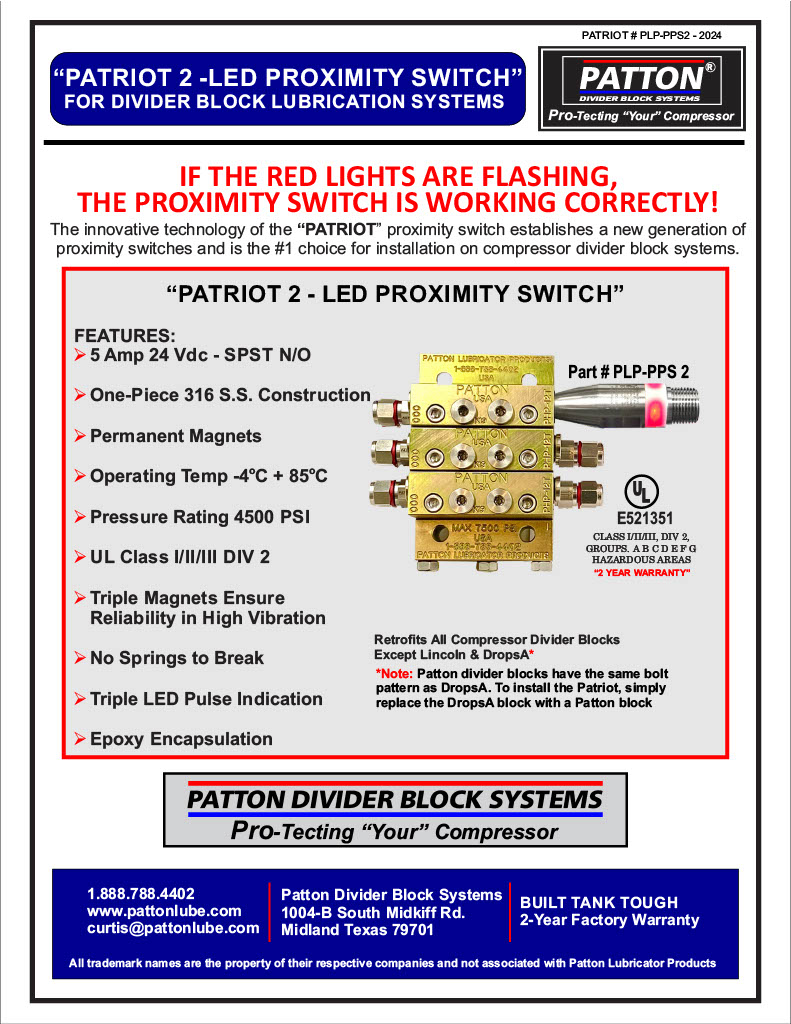

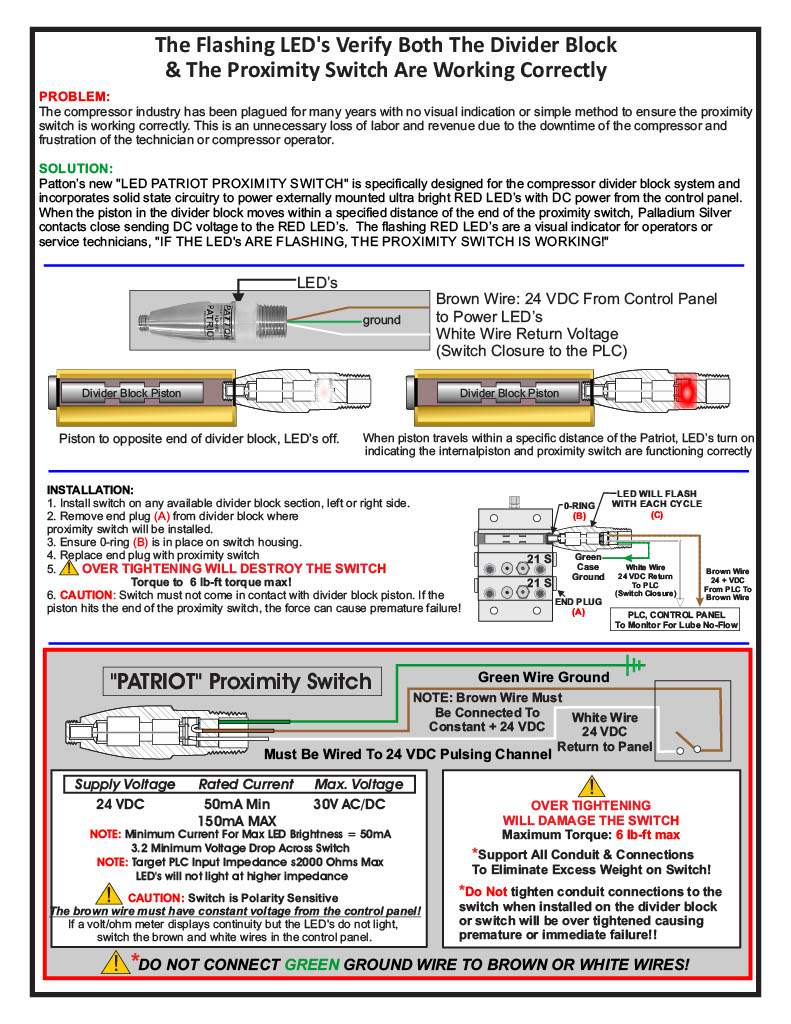

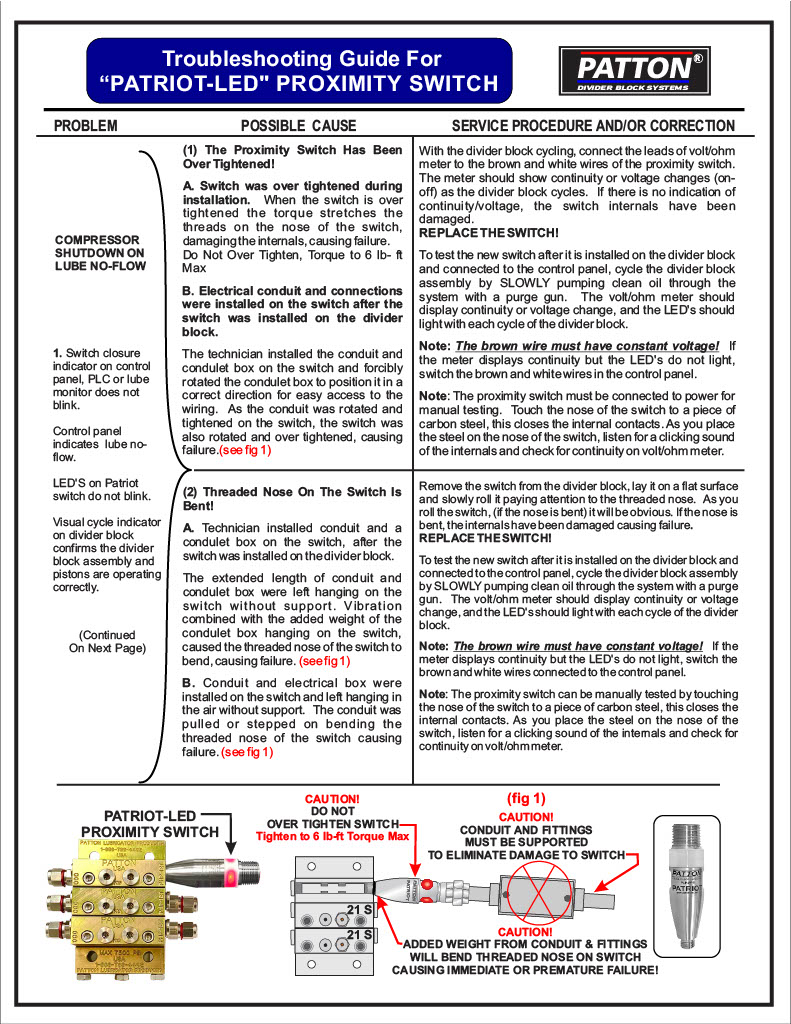

PATRIOT 2 -LED PROXIMITY SWITCH (Full PDF)

IF THE RED LIGHTS ARE FLASHING, THE PROXIMITY SWITCH IS WORKING CORRECTLY!

The innovative technology of the "PATRIOT" proximity switch establishes a new generation of proximity switches and is the #1 choice for installation on compressor divider block systems.

The Problem:

The compressor industry has been plagued for many years with no visual indication, or simple method to ensure the proximity switch is working correctly. This is an unnecessary loss of labor and revenue due to the extended downtime of the compressor and increased frustration of the technician or compressor operator.

The Solution: PATTON’S FIELD SENSITIVE BPS BULLET PROXIMITY SWITCH

Patton’s new "LED PATRIOT PROXIMITY SWITCH" is specifically designed for the compressor divider block system and incorporates solid state circuitry to power externally mounted ultra bright RED LED’s with DC power from the control panel. When the piston in the divider block moves within a specified distance of the end of the proximity switch, Palladium Silver contacts close, sending DC voltage to the RED LED’s. The flashing RED LED’s are a visual indicator for operators or service technicians, "IF THE LED's ARE FLASHING, THE PROXIMITY SWITCH IS WORKING!"

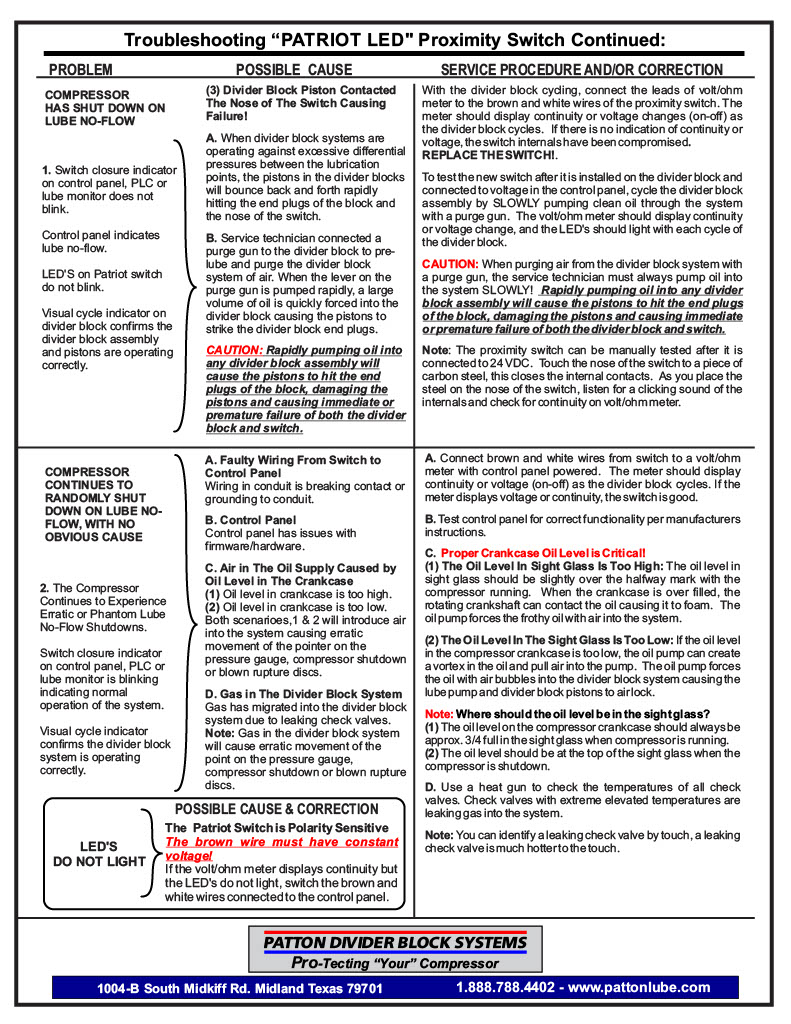

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

Low and High Pressure Filters

Low and High Pressure Filters

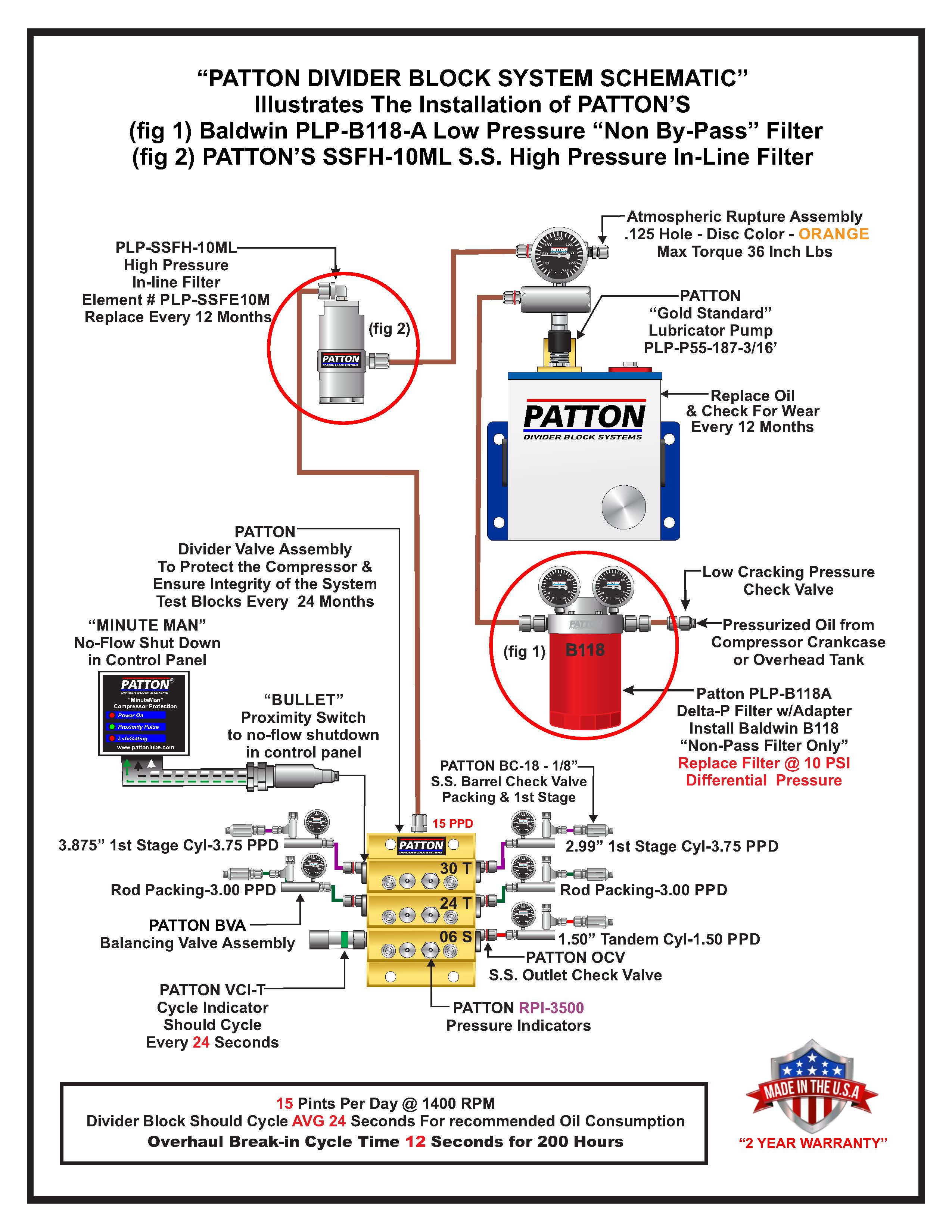

B118-A Delta-P Filter Assembly

The Patton "B118-A Delta-P Filter Assembly" is a low pressure non-bypass in-line filter. The low pressure filter must be installed upstream of the lubricator pump in the oil supply line. The B-118 filters trash out of the oil supply eliminating pump failure caused by debris in the oil. The delta-p across the filter is displayed on the 2" liquid filled pressure gauges to alert the operator when, "It's Time To Replace The Filter."

SSFH-10ML High Pressure Filter

The Patton "SSFH-10ML" High Pressure Filter should be installed in the oil supply line on the discharge side of the lube pump to remove suspended debris down to 10 Micron. Filtering oil eliminates divider block and check valve failure caused by trash. All divider block systems should have a high pressure in-line filter installed to increase reliability.

Product Brochure (click to expand or contract)

Product Installation Brochure (click to expand or contract)

Over Pressure Relief

Over Pressure Relief

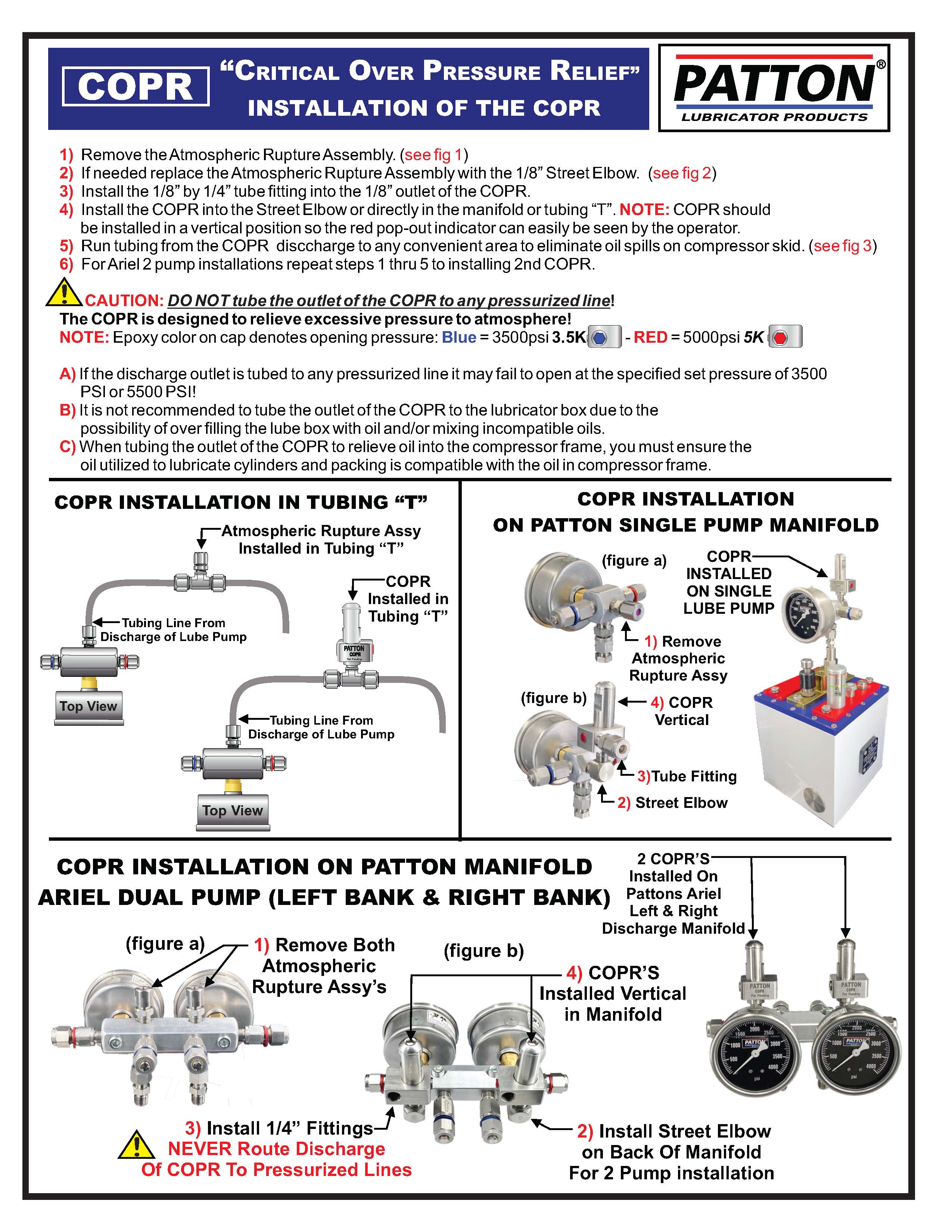

COPR (Critical Over Pressure Relief)

The Patton COPR replces atmospheric rupture discs on all divider block systems. When system pressure exceeds safe operating pressure limits, the COPR opens and shunts the oil to a resovoir or the lubricator box, eliminating the hazordous dumping of oil to the environment. The COPR is available in 3500 psi and 5500 psi configurations with higher pressure versions available if needed.

Product Brochure (click to expand or contract)

Product Installation Brochure (click to expand or contract)

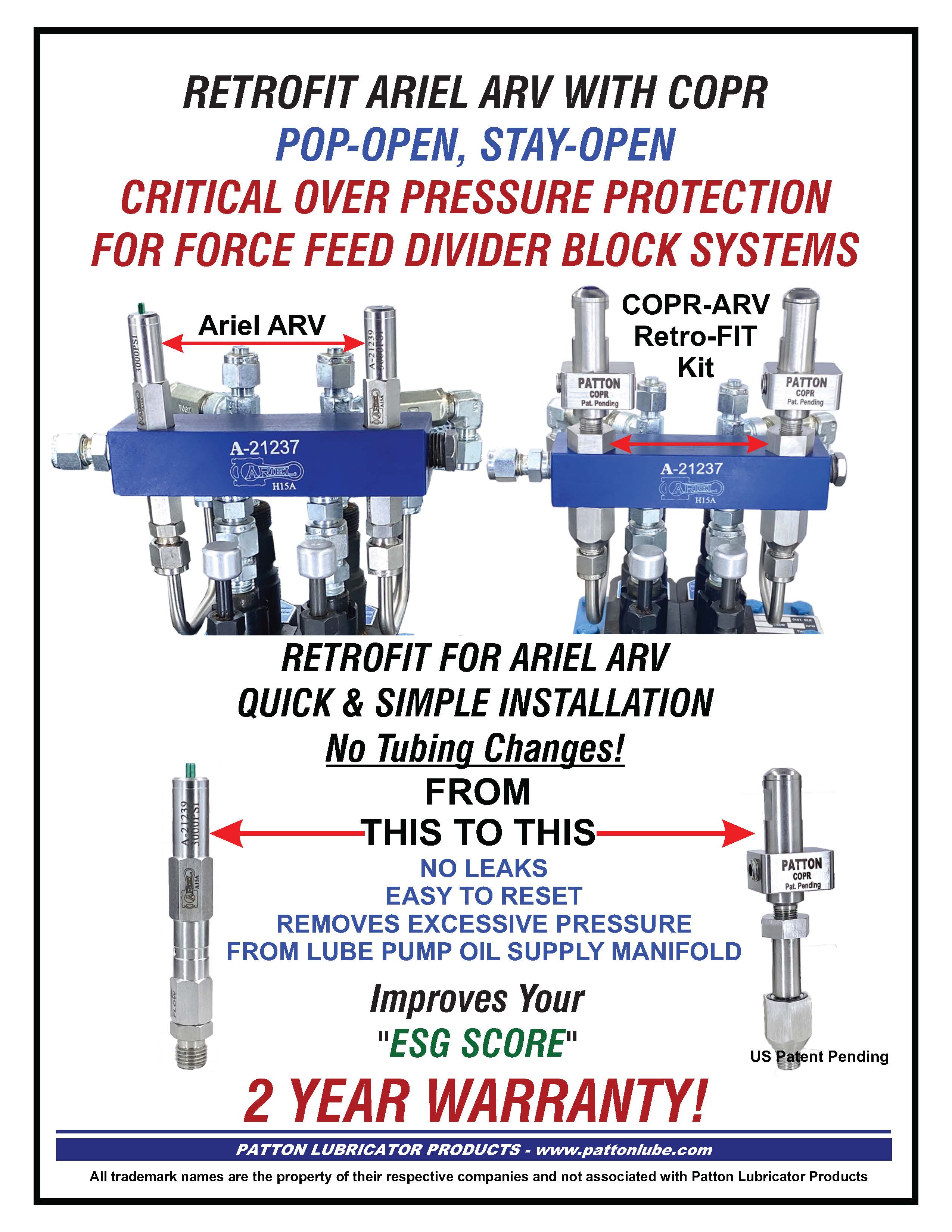

COPR-ARV Retrofit

Designed to enable compressor operators to retrofit the Ariel ARV with Patton's COPR or an Atmospheric Rupture Disc Assembly.

Product Brochure (click to expand or contract)

Product Installation Brochure (click to expand or contract)

No-Flow Shutdown

"MinuteMan" No-Flow Shutdown

Revolutionary Design

The Minuteman no-flo device can be mounted anywhere on the compressor frame, skid, control panel or wall mount because it is no longer coupled mechanically to the proximity switch. The operation can be set to either a normally open or normally closed configuration. The Minuteman No-Flo device has a Form C alarm output as well as a traditional LED proximity switch pulse indicator. This fully encapsulated device comes with a 2 year factory warranty and can operate in temperatures from -4 degrees C to +80 degrees C.

Product Brochure (click to expand or contract)

Product Brochure (click to expand or contract)

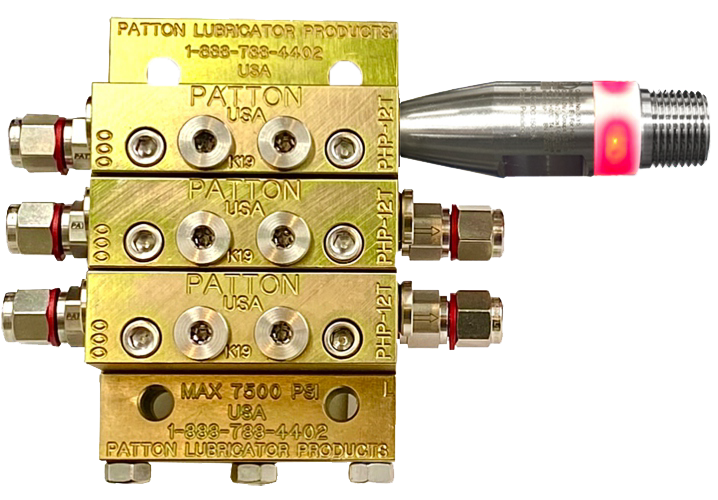

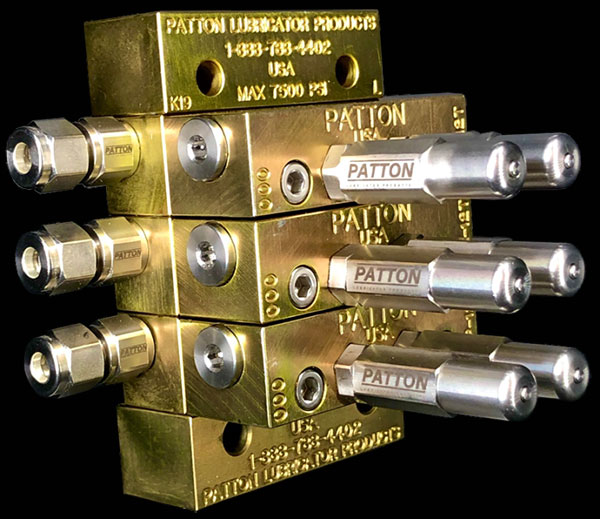

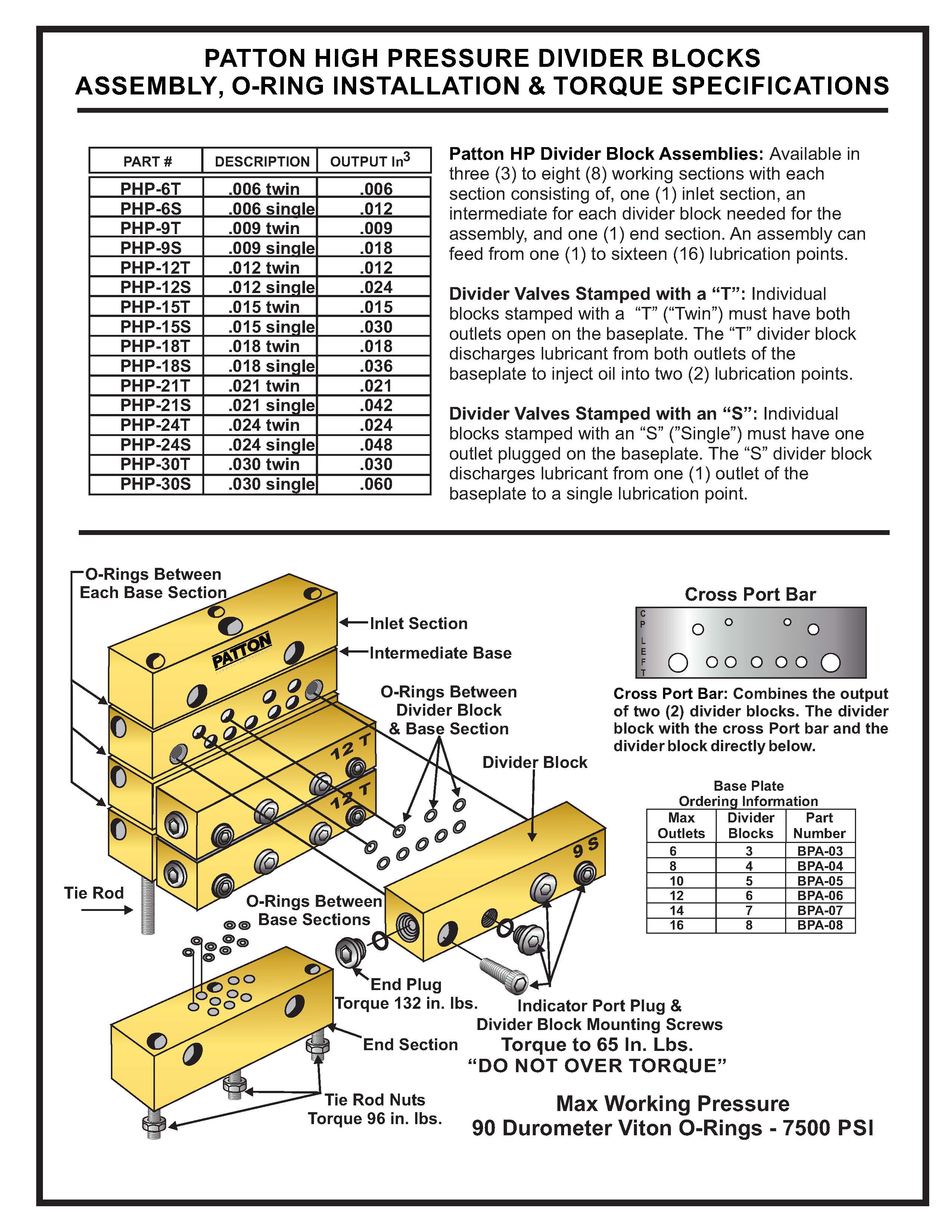

Divider Block

Patton HP Divider Block

When You Can’t Afford Failures or Downtime!

Positive Lubrication:

The Patton HP divider block assemblies have the tightest piston to valve tolerance in the world at 80 to 90 millions-of-an-inch! This incredibly tight tolerance both ensures precise amounts of lubrication to vital components as well as superior piston stalling for positive shutdown of the system if any lubrication point plugs.

High Pressure Capability:

The Patton HP divider blocks are designed to be assembled and mounted with reduced torque of only 65 inch pounds. This assures a leak free operation to 7,500 PSI.

More Piston Options:

Patton HP divider block pistons come in more sizes so systems can be designed to deliver lubrication quantities at a more efficient rate. This saves money in lubrication costs.

O-Ring Outlet Checks:

Patton HP divider blocks come with O-Ring outlet check valves. This reduces leak paths and assures the reliable operation of your divider blocks.

Product Brochure (click to expand or contract)

Product Installation Brochure (click to expand or contract)

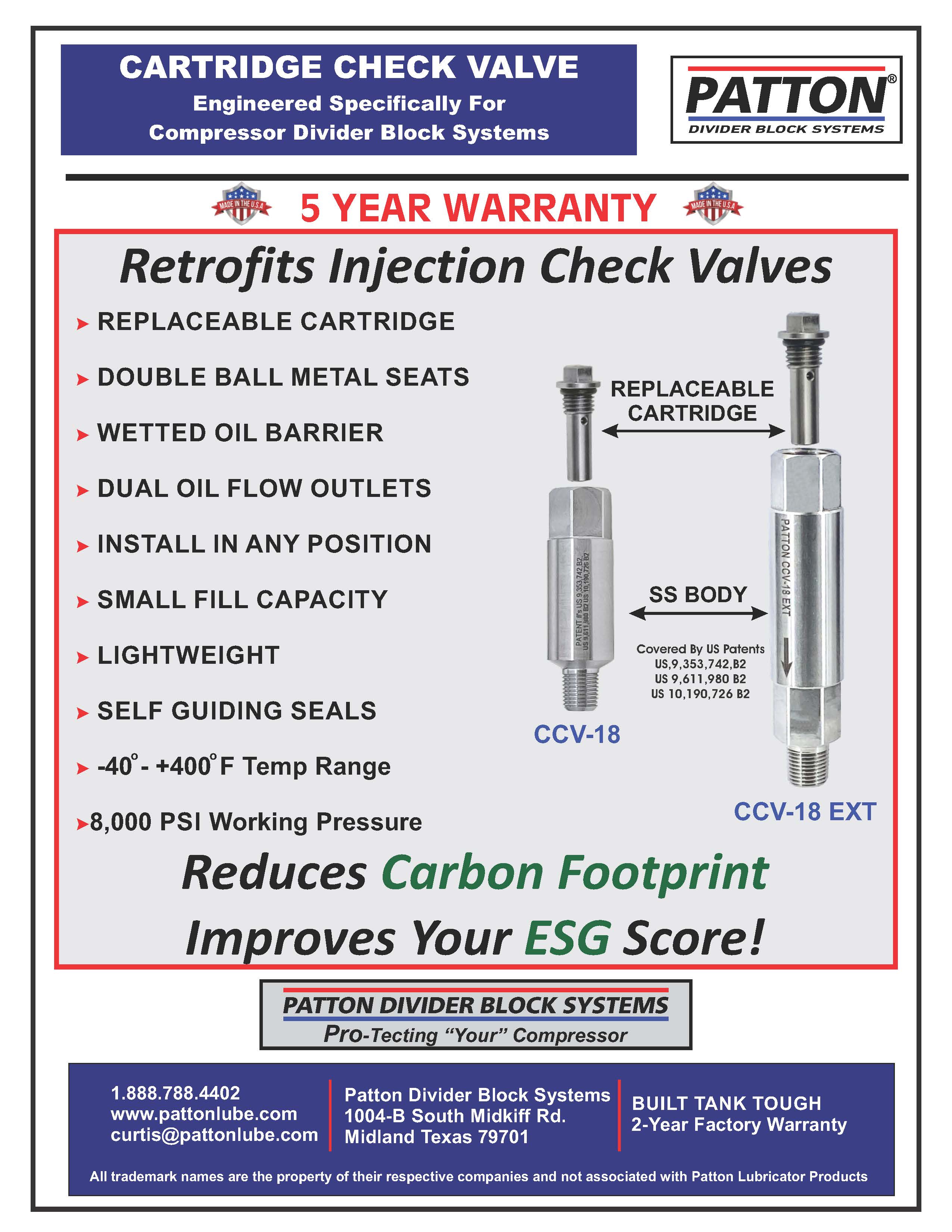

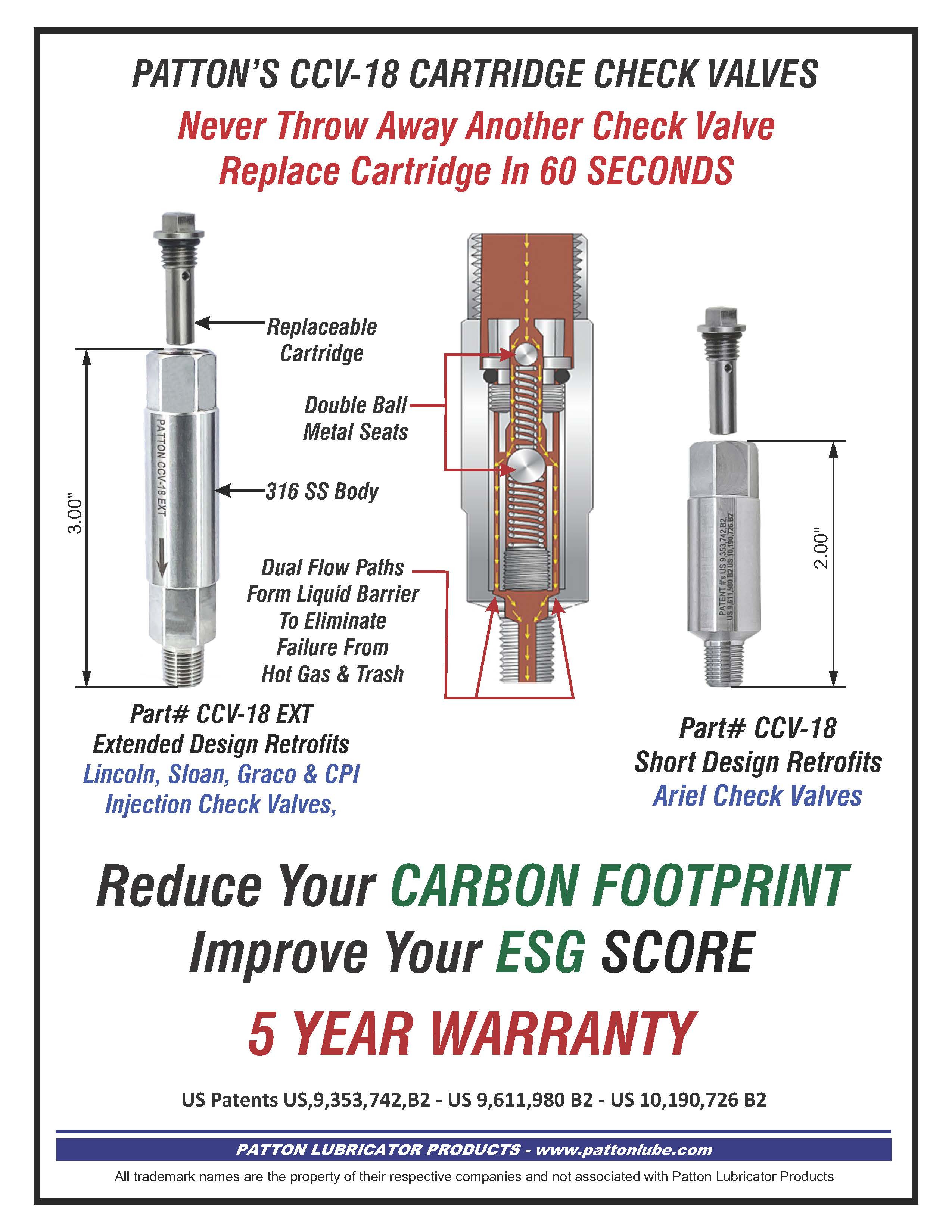

Cartridge Check Valve

Patton Cartridge Check Valve

Engineered Design Protects Itself Against Failure.

Replaceable Cartridge:

Field rebuild in 60 seconds.

Double Ball Metal to Metal Seats

Increased longevity and reliability.

Wetted Oil Barrier:

Protects sealing surfaces from hot gas for extreme durability.

Dual Oil Flow Outlets:

Extended service life.

Install in any position:

Works equally well in any position.

Small Fill Capacity:

Timely injection of lubricant extends longevity and reliability of compressor cylinders, rods and packing gland.

Lightweight:

Lightweight design eliminates check valve failure caused by vibration.

Self Guiding Sealing Components:

Internal ball checks are self guiding which increases reliability.

Improves Your ESG Score:

Rather than disposing of an entire unit, only the cartridge needs to be disposed of.

Product Brochure Page 1 (click to expand or contract)

Product Brochure Page 2 (click to expand or contract)

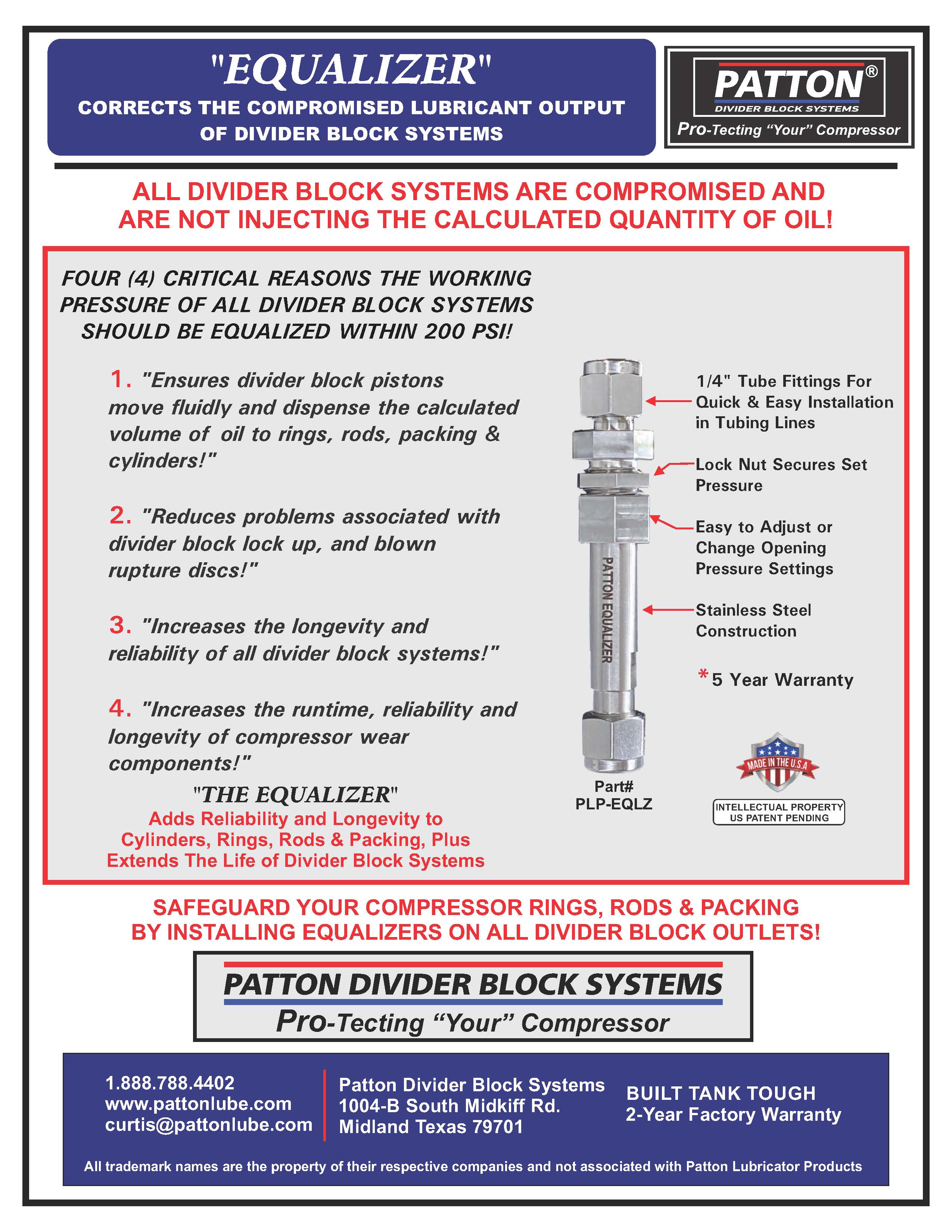

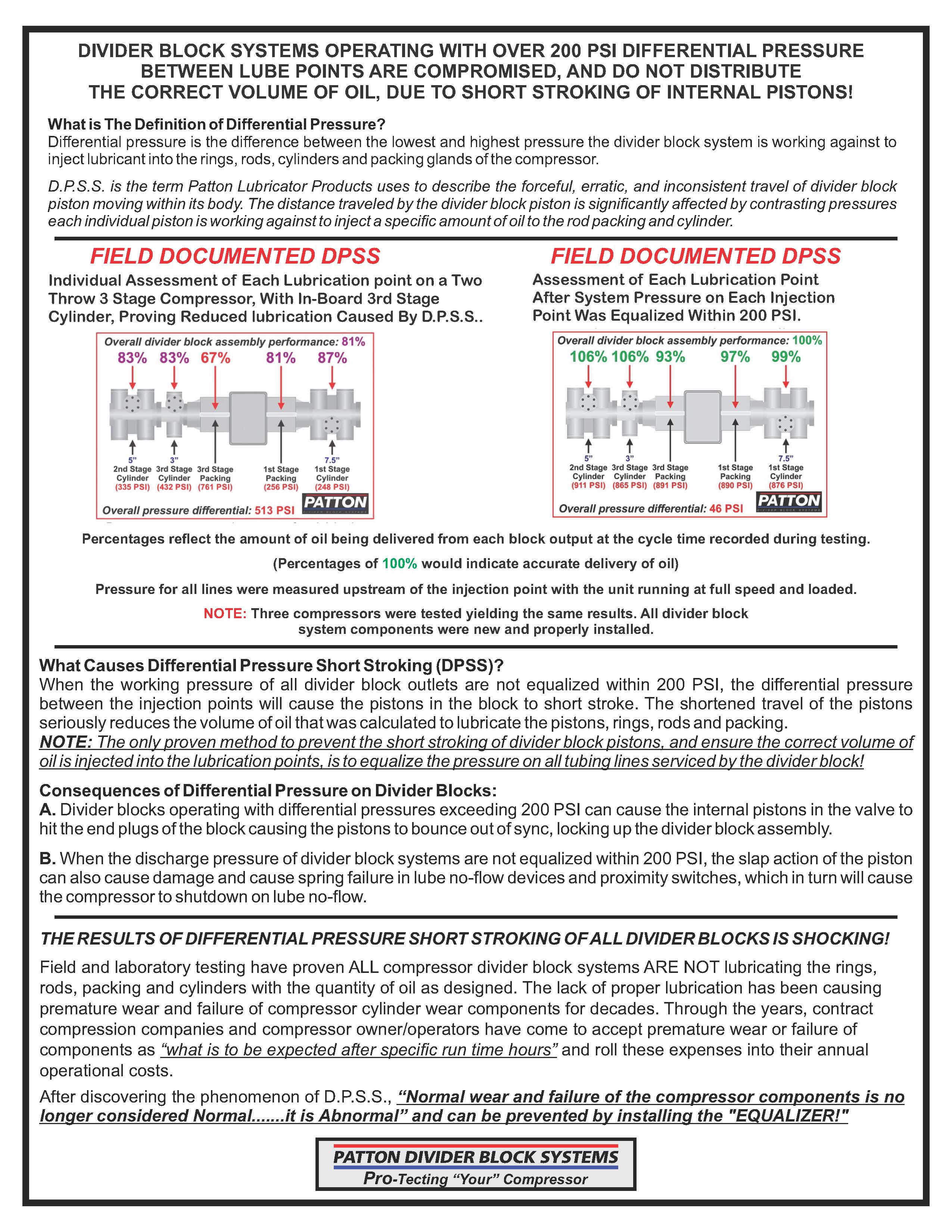

High Pressure Lubrication Equalization Products

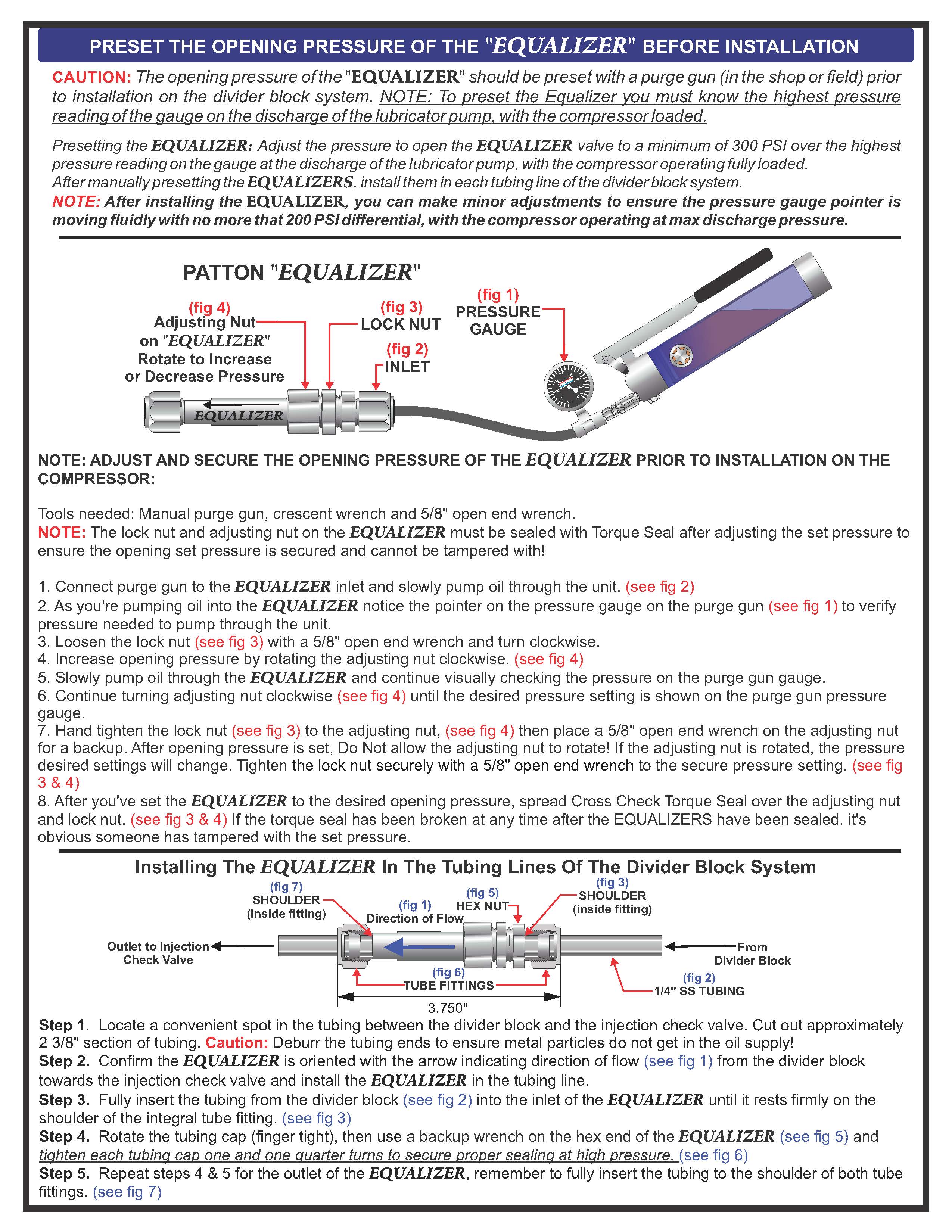

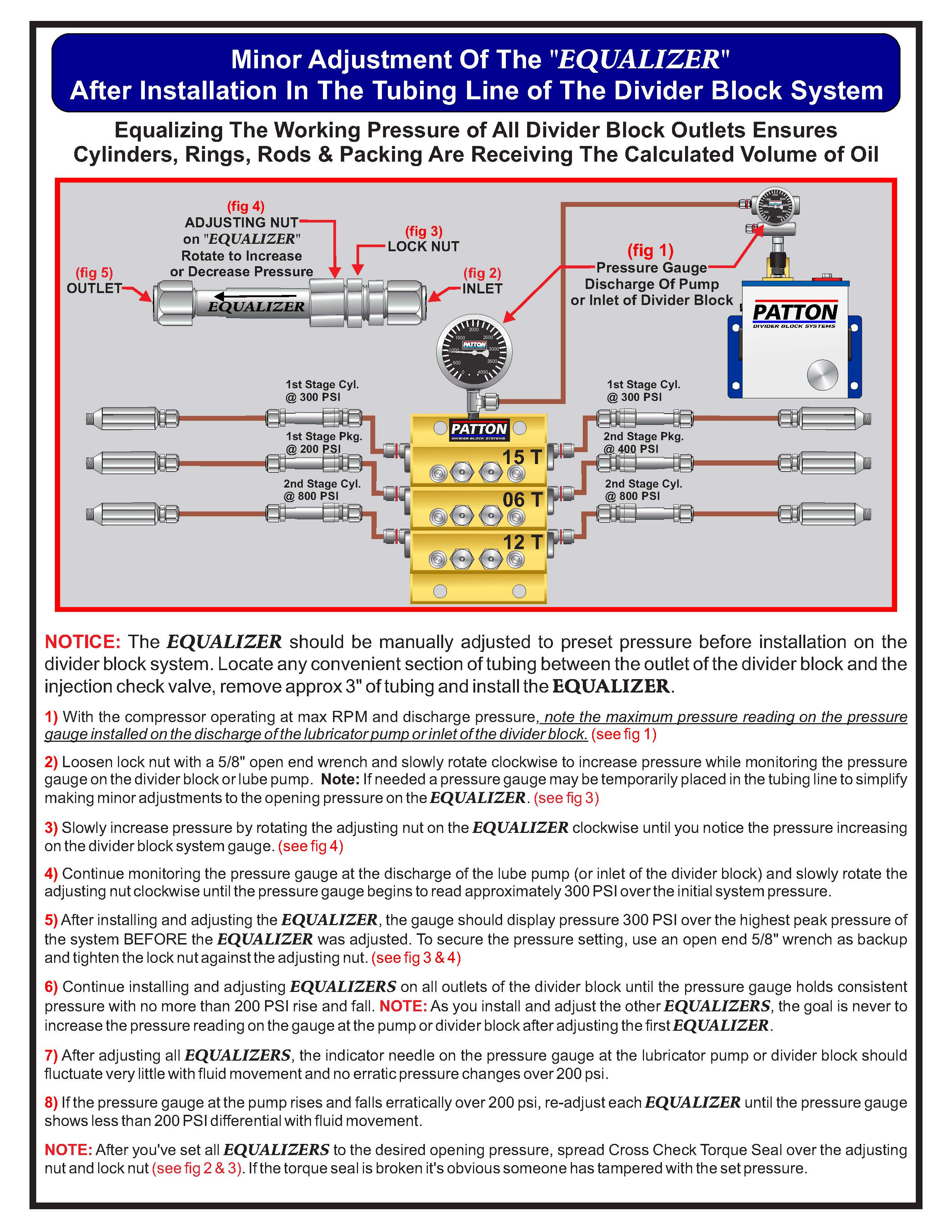

Patton Equalizer

All compressors are not being lubricated correctly by the divider block systems!

Ensure proper lubrication:

Ensures divider block pistons move fluidly and dispense the calculated volume of oil to rings, rods, packing and cylinders!

Reduce Maintenance:

Reduces problems associated with divider block lock up, and blown rupture discs!

Longer Component Life:

Increases the longevity and reliability of all divider block systems!

Decreased Downtime:

Increases the runtime, reliability and longevity of compressor wear components!

Product Brochure Page 1 (click to expand or contract)

Product Brochure Page 2 (click to expand or contract)

Product Brochure Page 3 (click to expand or contract)

Product Brochure Page 4 (click to expand or contract)

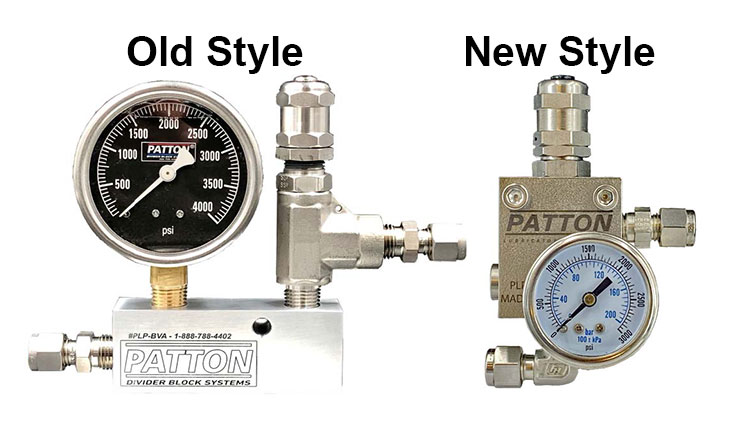

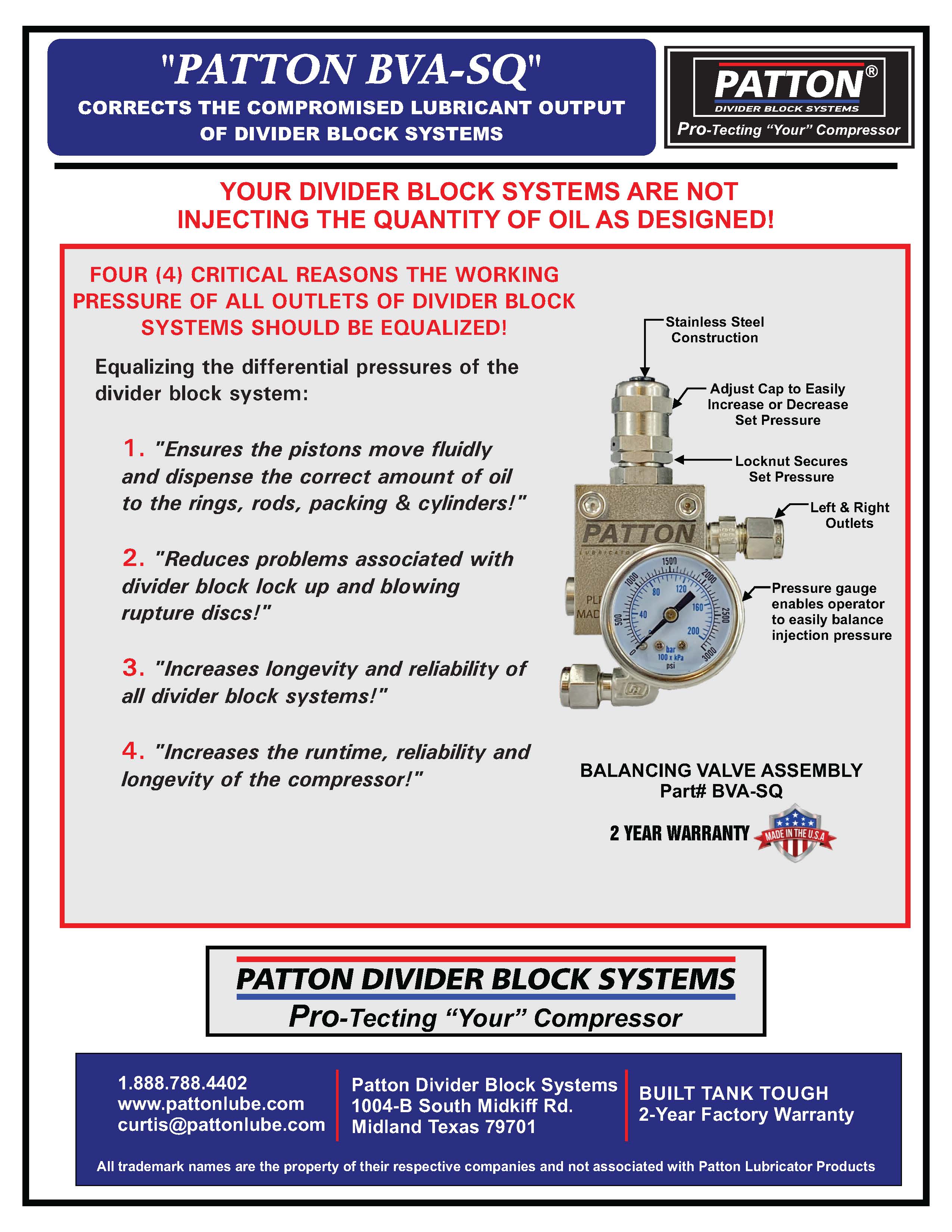

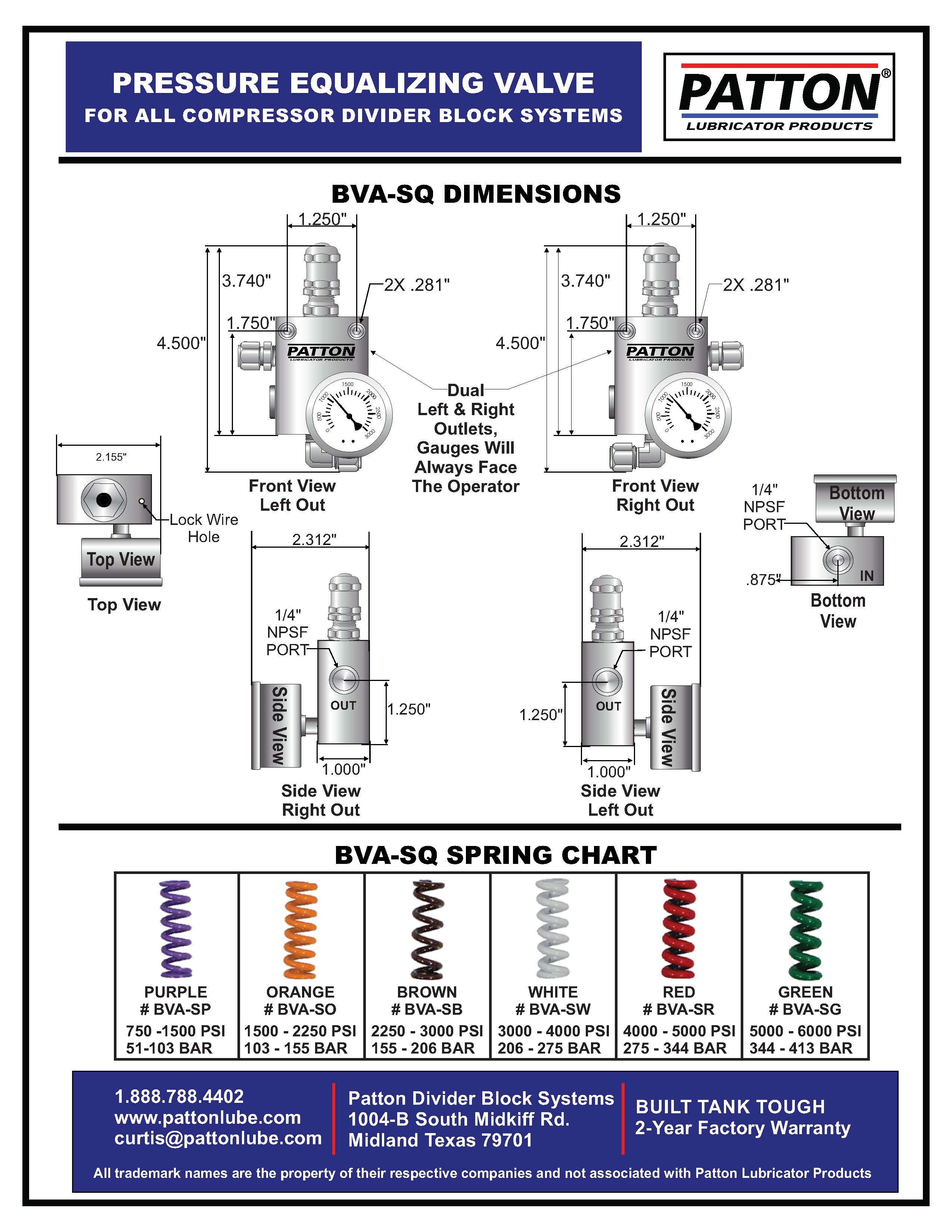

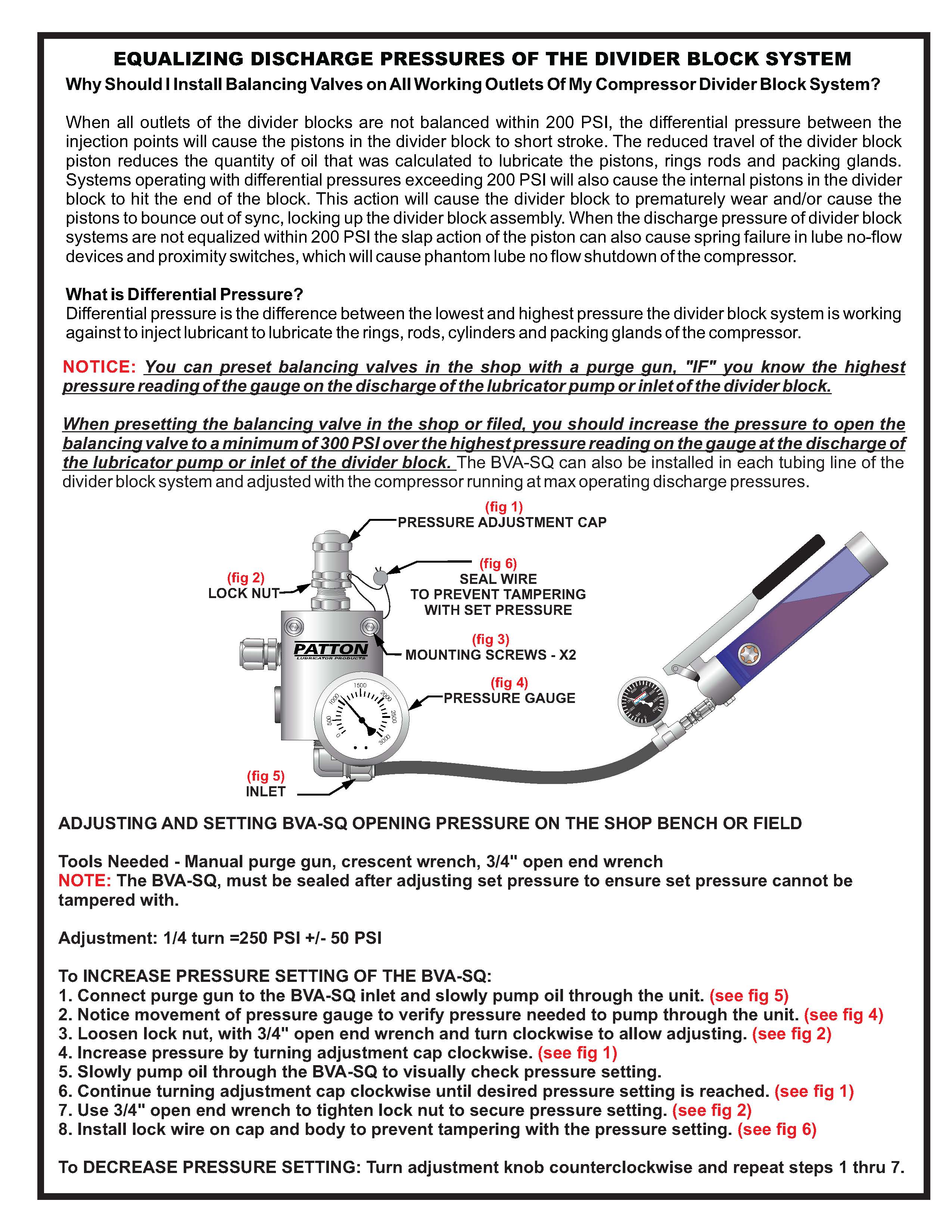

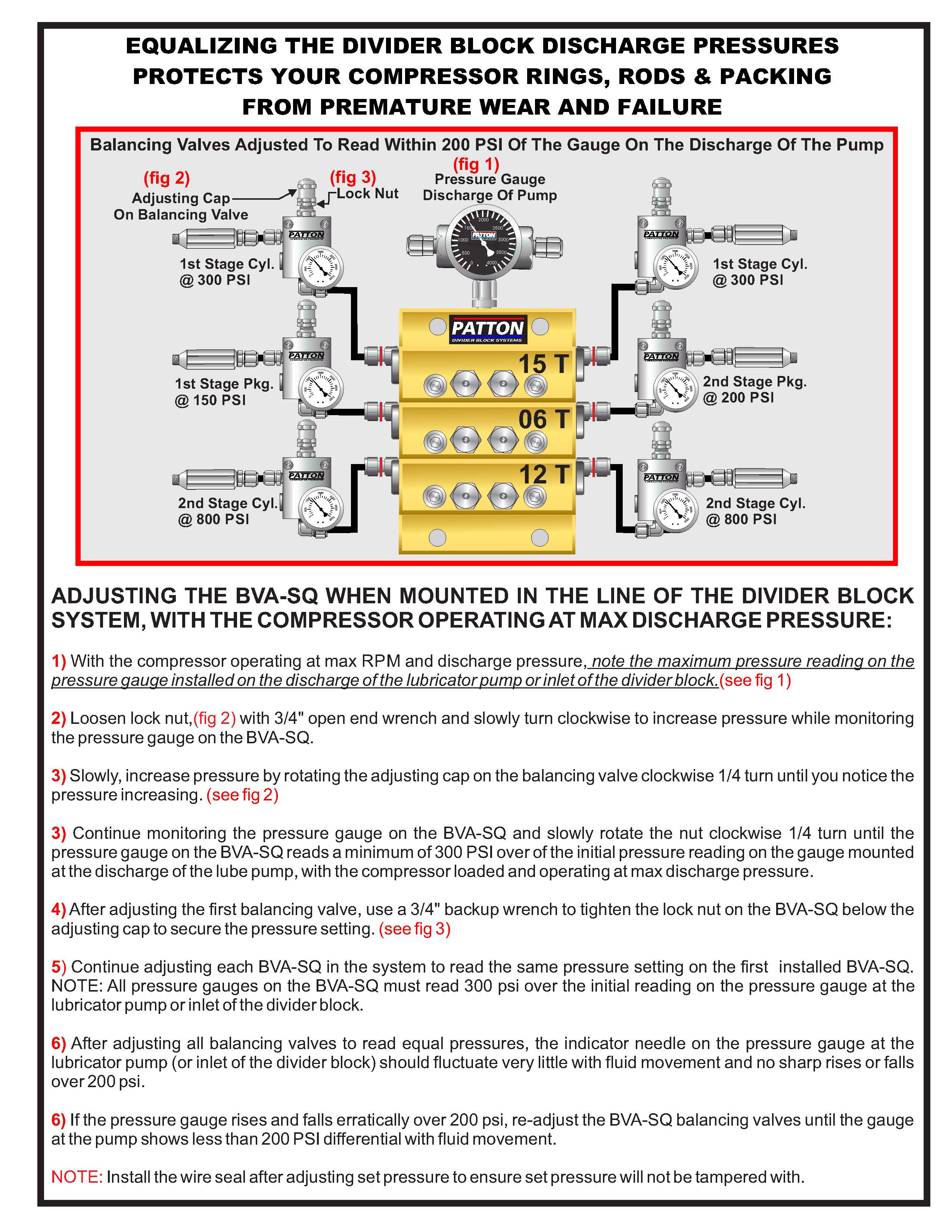

BVA SQ

Stop Premature Wear and Failure of High Pressure Divider Block Systems

Spring Breakage:

Ensures the pistons move fluidly and dispense the correct amount of oil to the rings, rods, packing and cylinders

Premature Wear:

Reduces problems associated with divider block lock up and blowing rupture discs

Blown Rupture Disc Issues:

Increases longevity and reliability of all divider block systems

Piston By-Passing:

Increases the runtime, reliability and longevity of the compressor

BVA Overview (click to expand or contract)

BVA Specs (click to expand or contract)

BVA Installation (click to expand or contract)

BVA Installation continued (click to expand or contract)

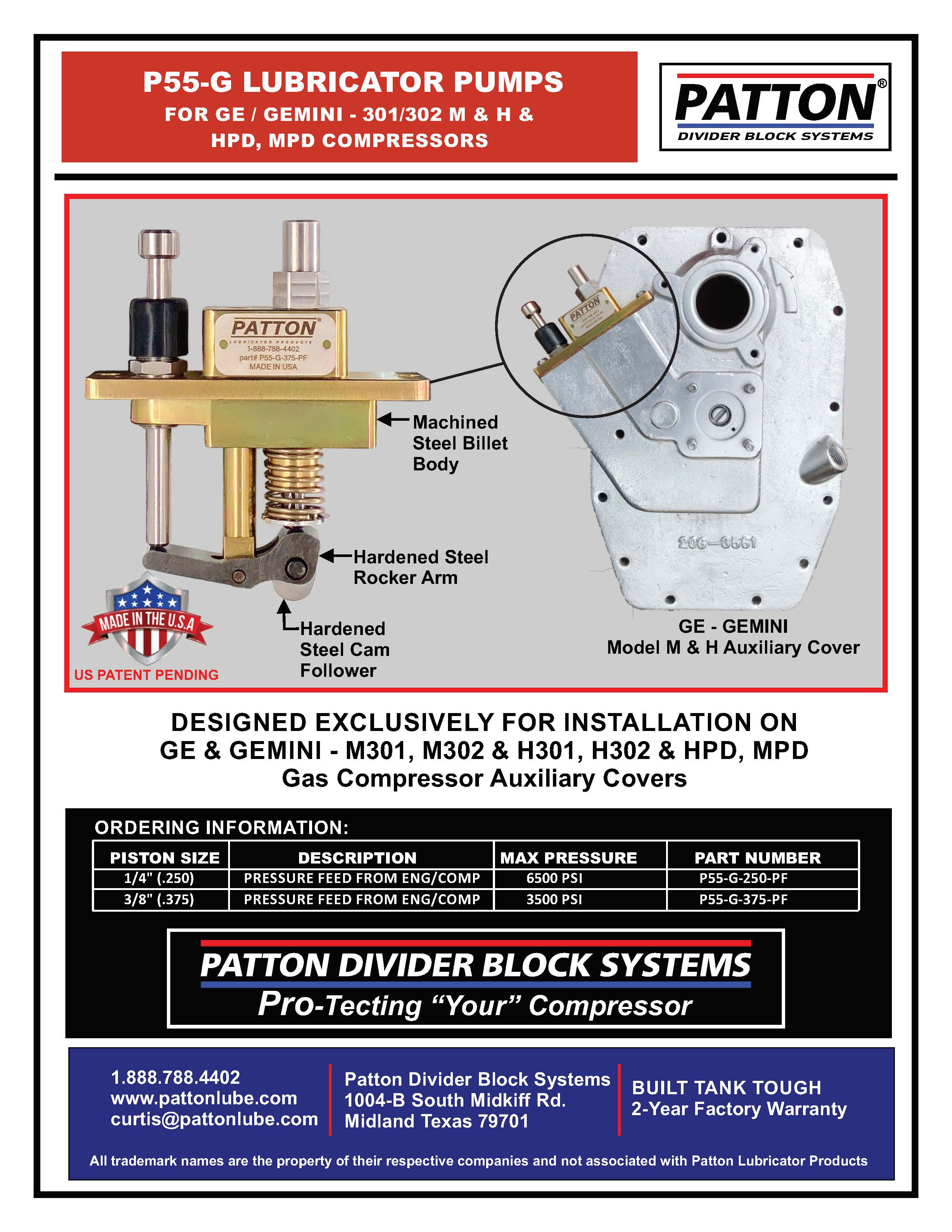

Pressure Feed Pump

Patton Pressure Feed Pump

For Reliable Lubrication of Compressor Cylinders, Rings, Rods and Packing

Machine Billet Body:

Machined from a single billet for strength.

Compatibility:

Compatible with ARIEL, CPI, LINCOLN, GRACO, TRABON and PREMIER lubricator boxes.

Hardened Steel Roller:

Hardened steel roller rocker arm for extreme pressure applications.

Lubricants:

Suitable for all lubricants.

Environment:

Weather proof and corrosion resistant construction:

Pressure Fed Pumps Brochure (click to expand or contract)

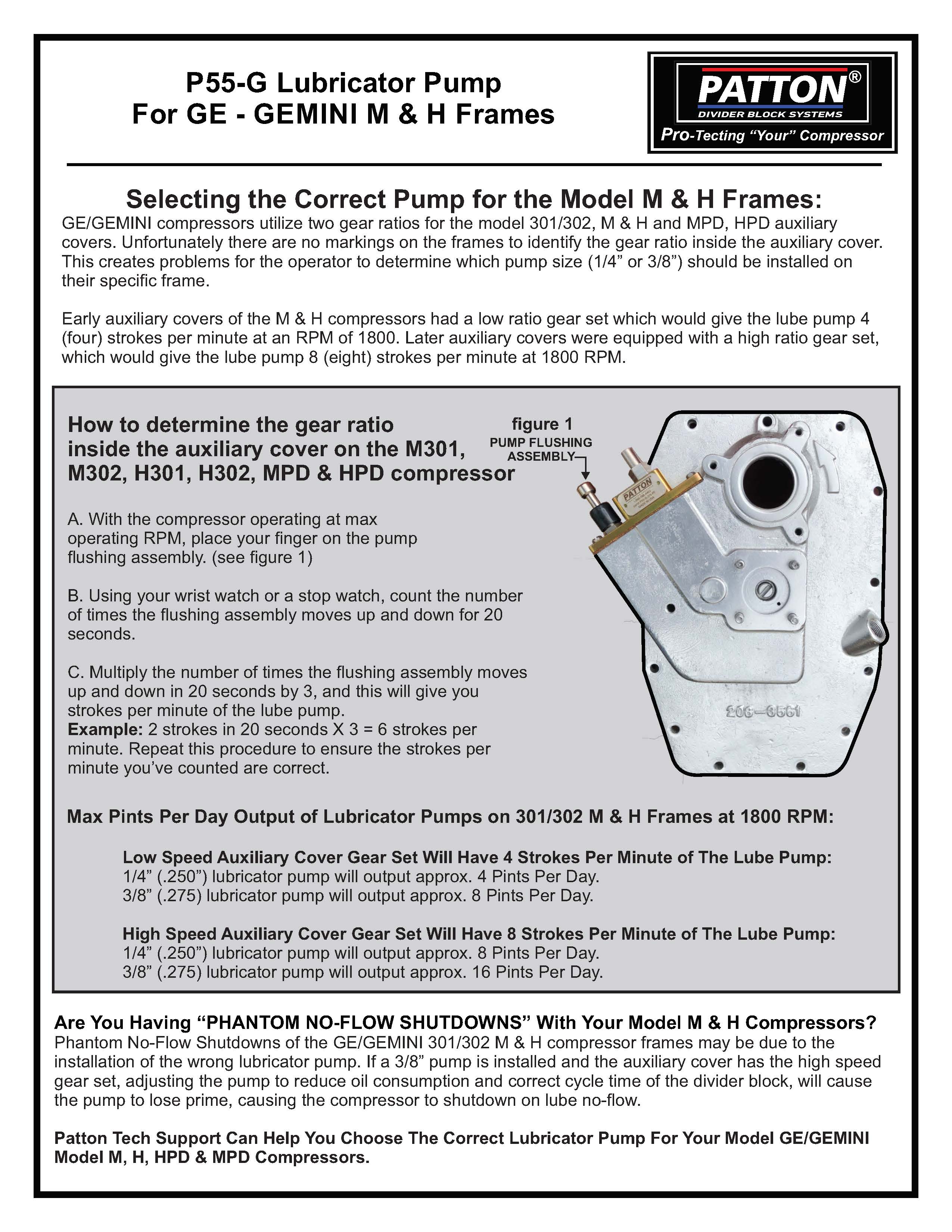

GE/Gemini Pumps Brochure (click to expand or contract)

GE/Gemini Pumps Installation Brochure (click to expand or contract)

Box Suction Pump

Patton Box Suction Pump

For Reliable Lubrication of Compressor Cylinders, Rings, Rods and Packing

Stainless Steel Body:

One piece stainless steel body with stainless steel components.

Compatibility:

Compatible with CPI, LINCOLN, GRACO, TRABON and PREMIER lubricator boxes.

Hardened Steel Roller:

Hardened steel roller rocker arm for extreme pressure applications.

Lubricants:

Suitable for all lubricants.

Environment:

Weather proof and corrosion resistant construction:

Suction Fed Pumps Brochure (click to expand or contract)

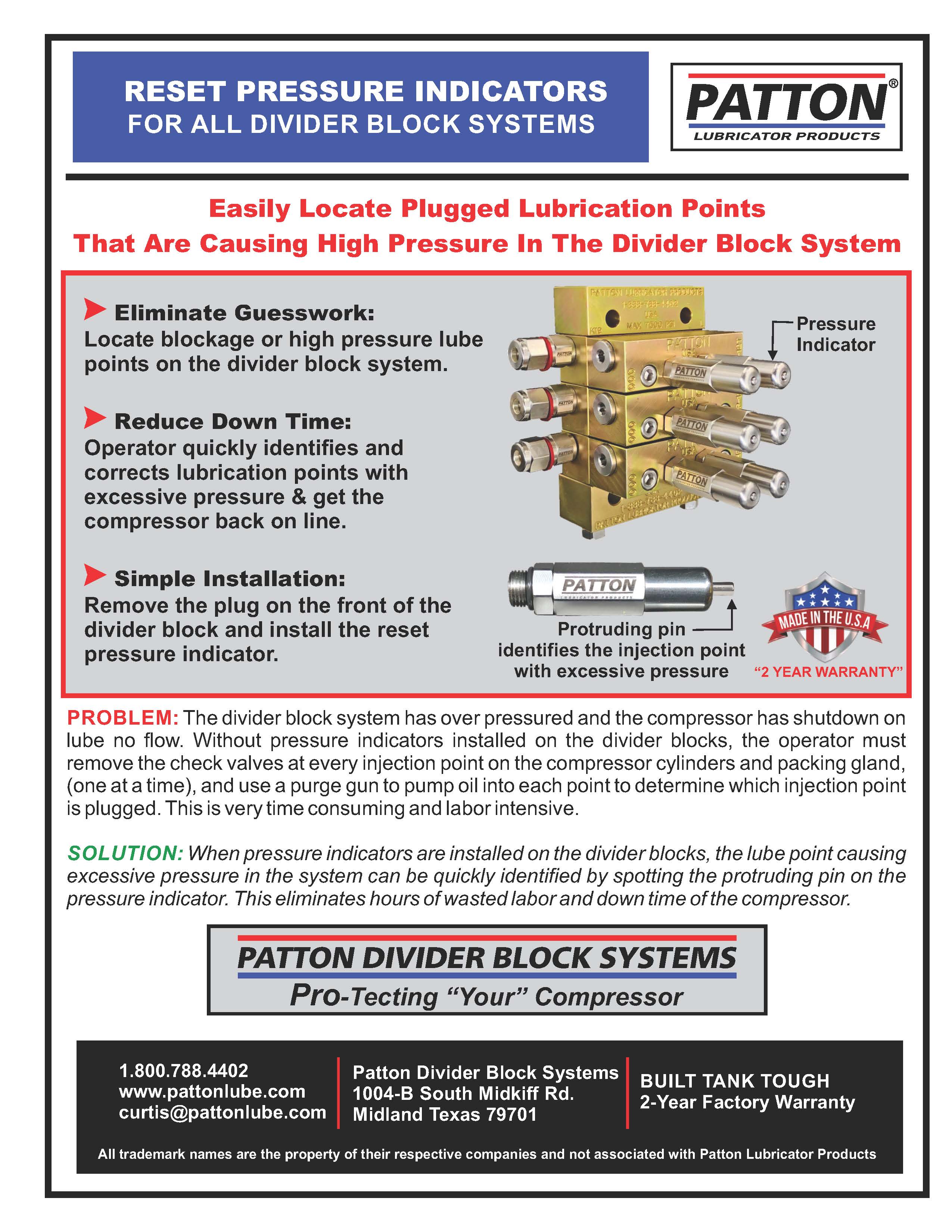

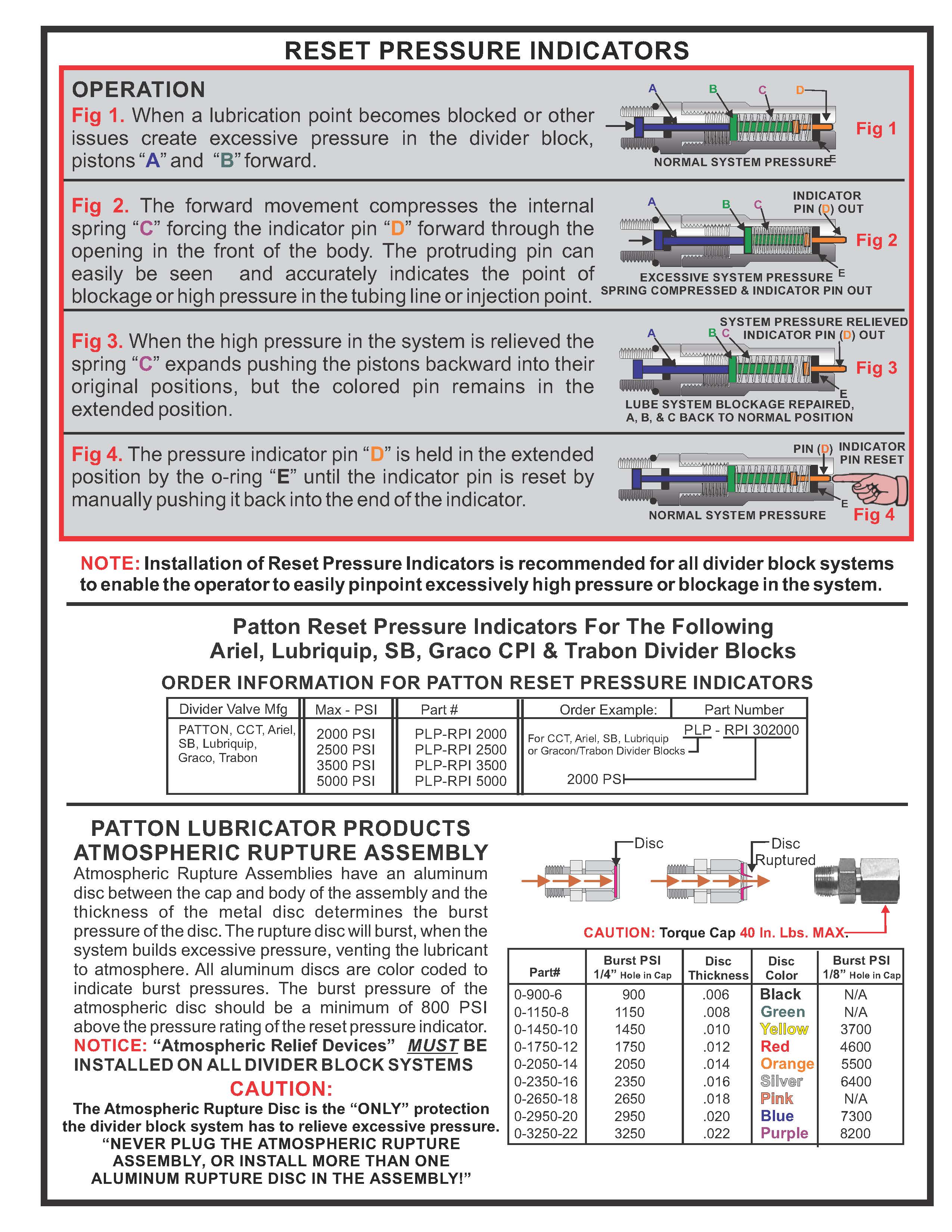

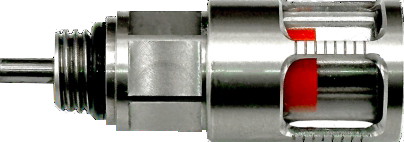

Reset Pressure Indicator

Patton Reset Pressure Indicator

Instantly Locate Lube Points Causing High Pressure in the Divider Block Lubrication System

Eliminate Guesswork:

Locate blockage or high pressure lube points on the divider block system "IMMEDIATELY"!.

Reduce Compressor Down Time:

Operator can quickly identify and correct problems with excessive pressure and get the compressor back on line.

Simple Installation:

Remove the plug on the front of the divider block and install the reset pressure indicator.

Cycle Indicator Brochure (click to expand or contract)

Cycle Indicator Installation Brochure (click to expand or contract)

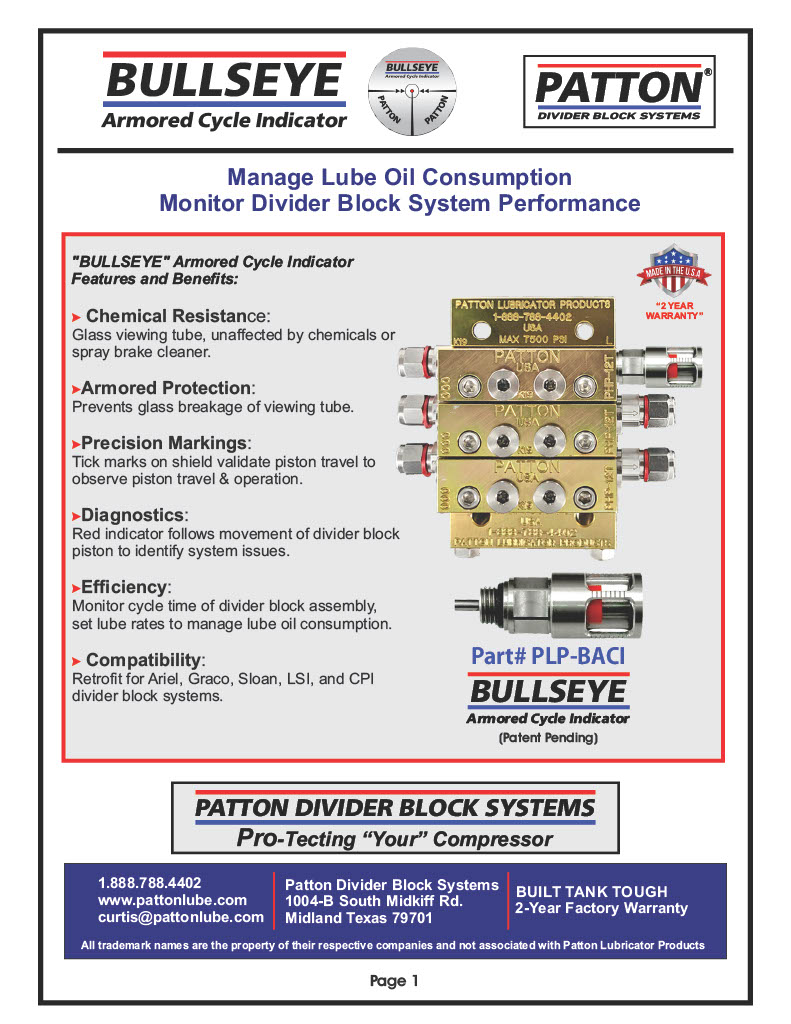

Cycle Indicator

Patton Cycle Indicator "Bullseye"

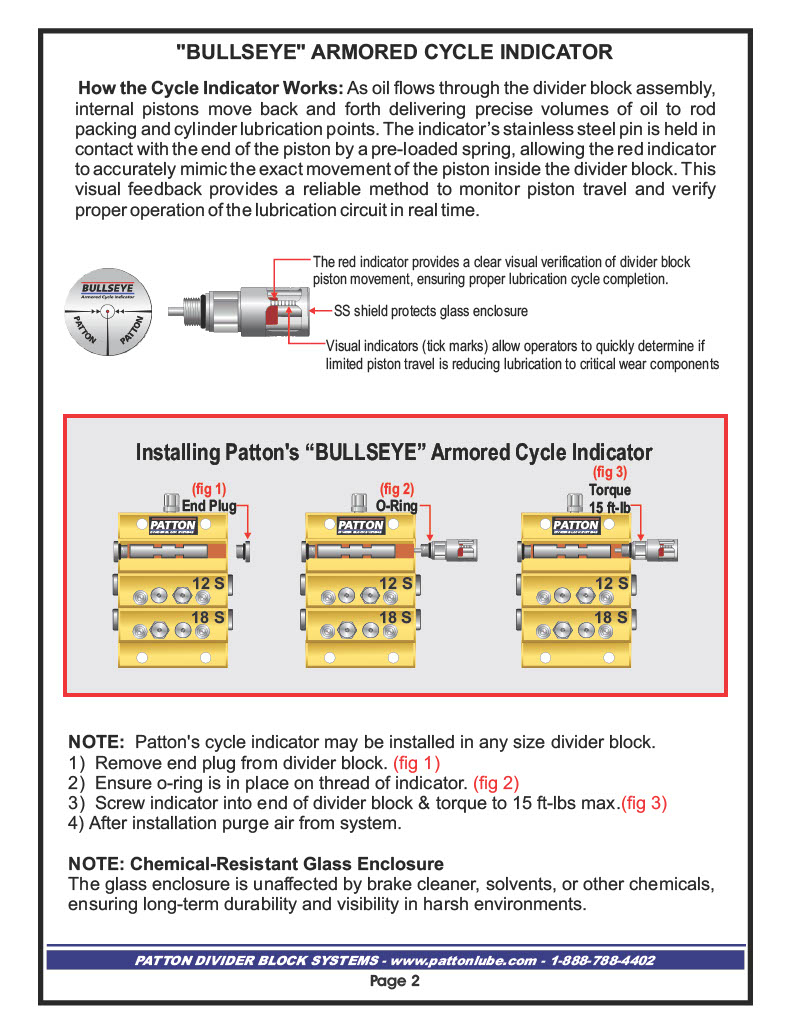

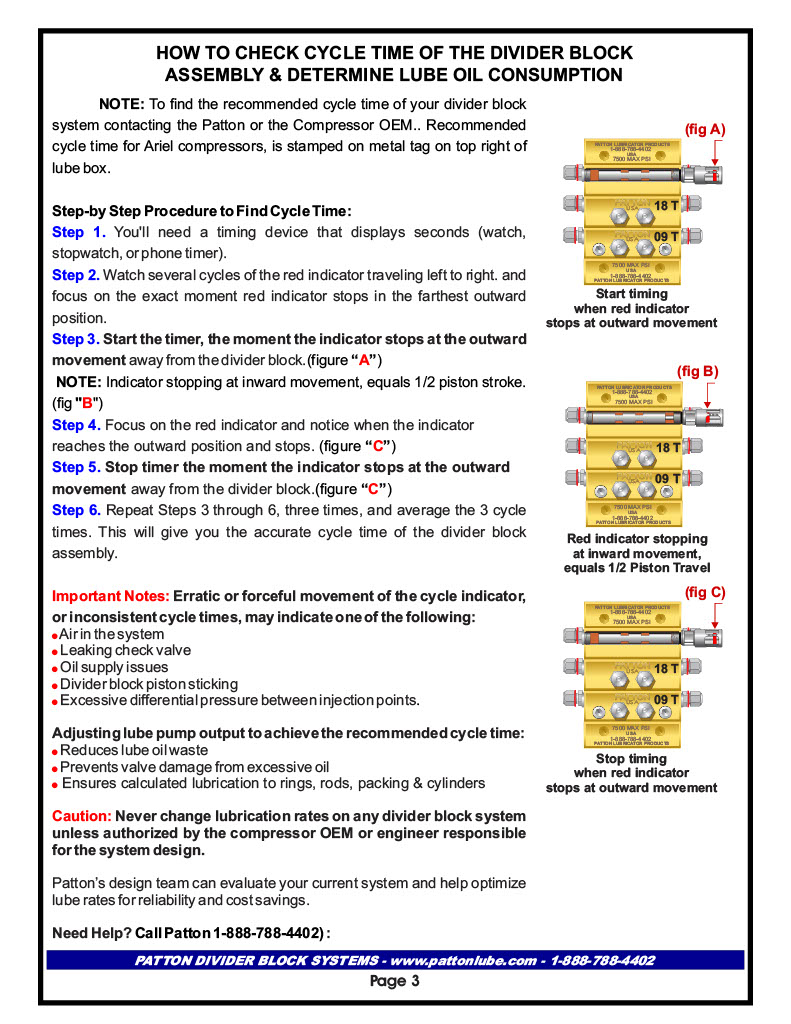

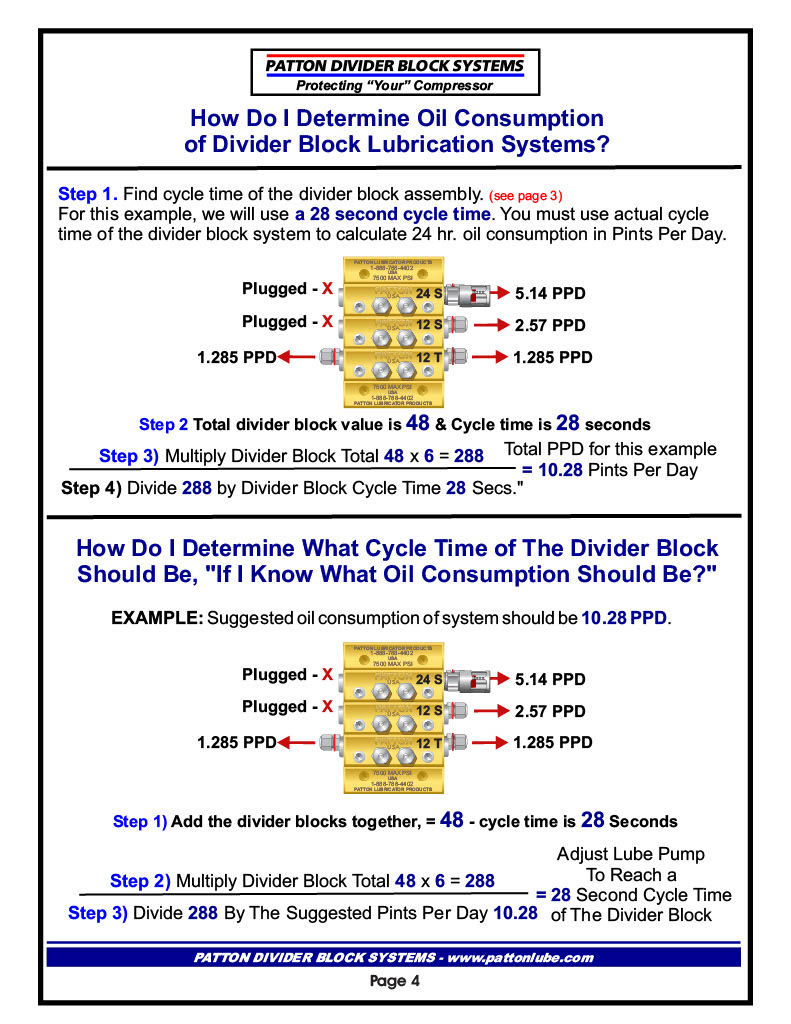

Set Lube rates and monitor the operation of the divider block system. (Full PDF)

Cycle Indicator Brochure (click to expand or contract)

Cycle Indicator Installation Brochure (click to expand or contract)

Cycle Indicator Installation Brochure (click to expand or contract)

Cycle Indicator Installation Brochure (click to expand or contract)

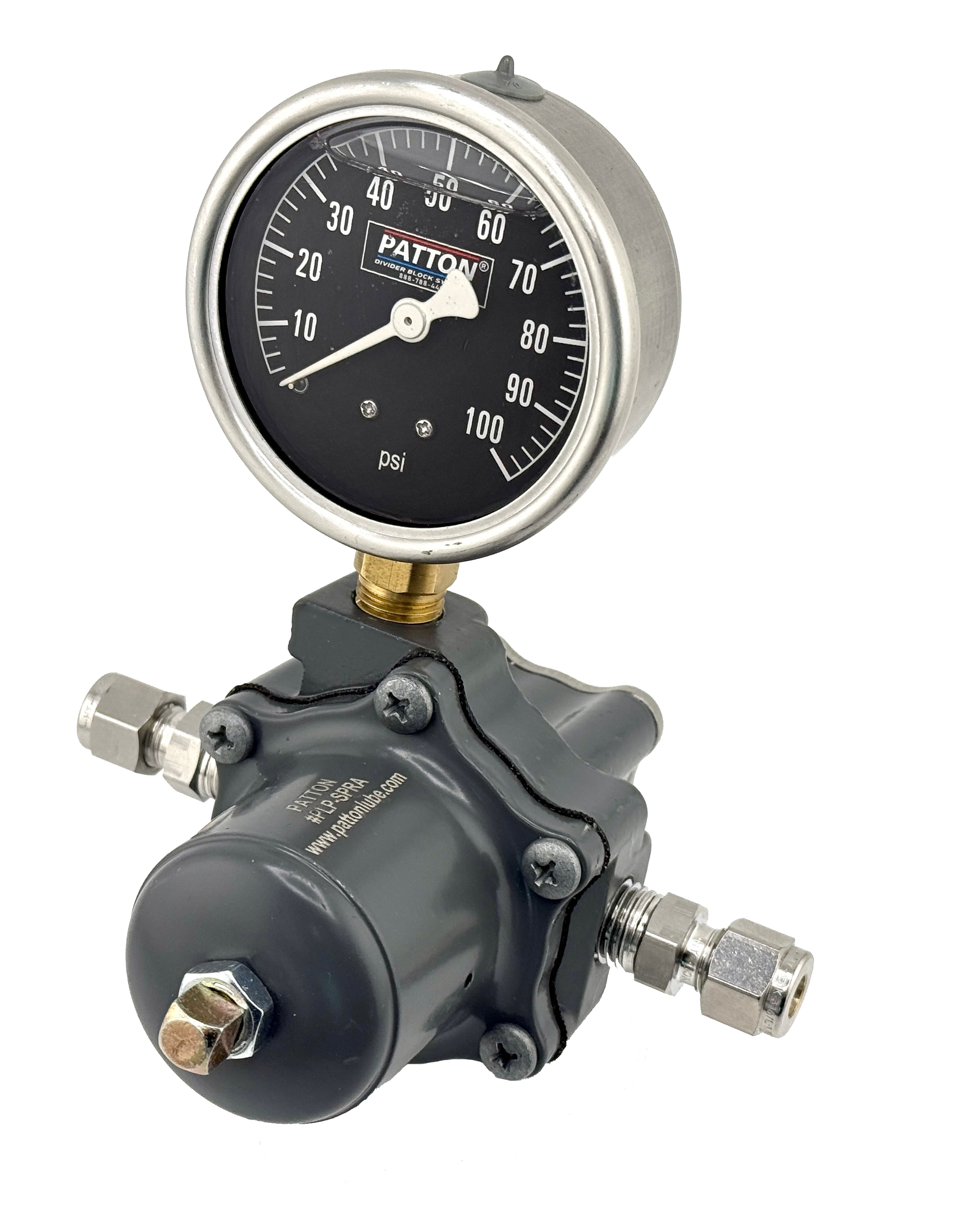

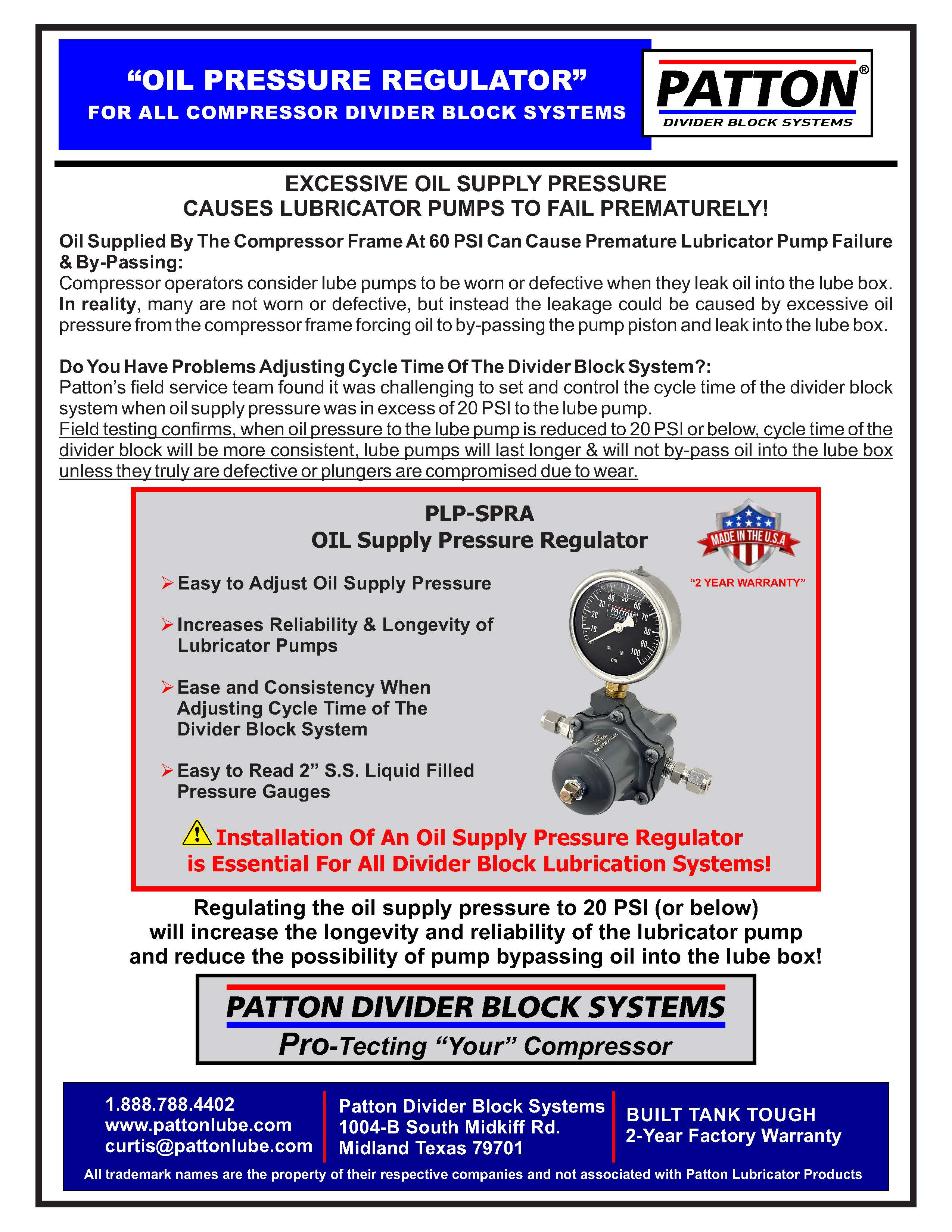

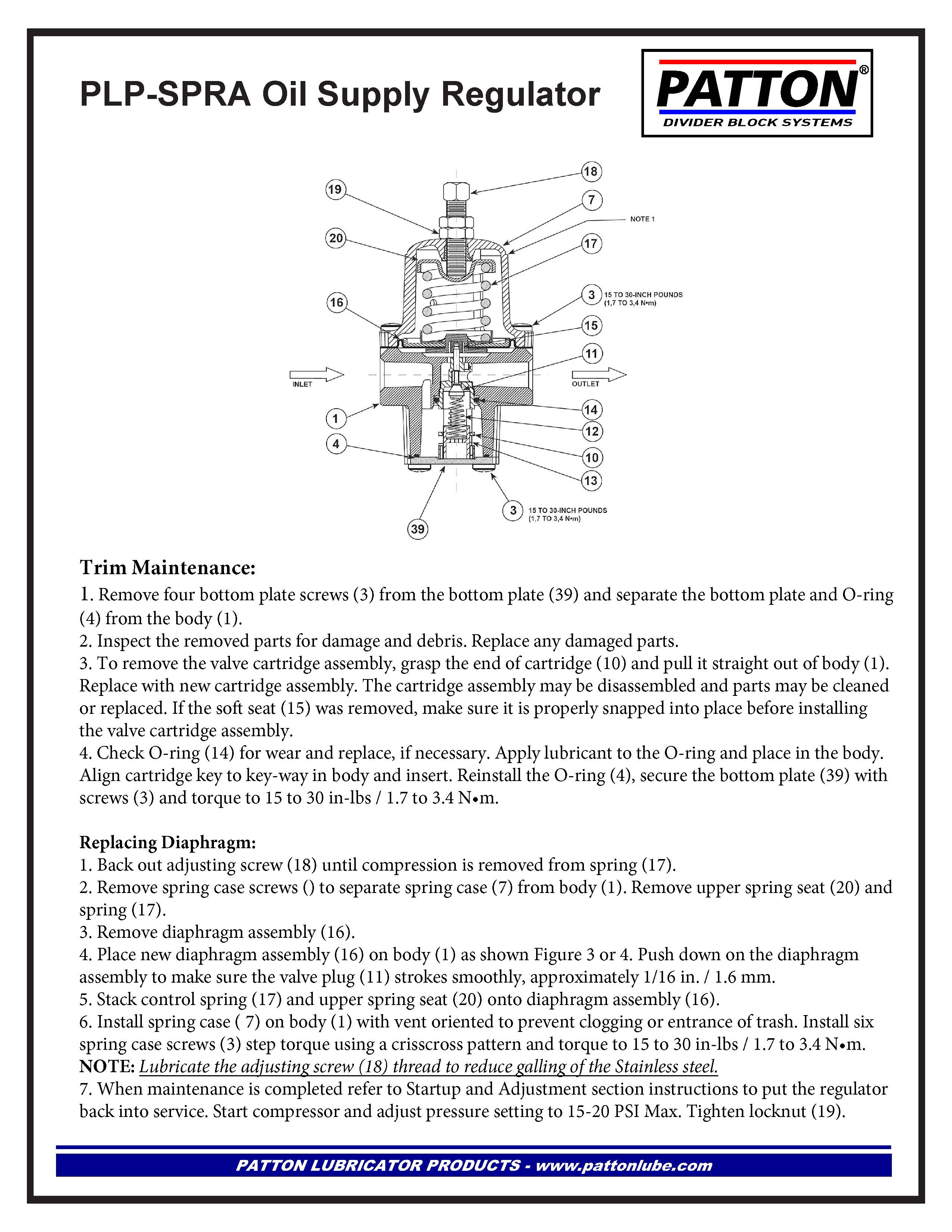

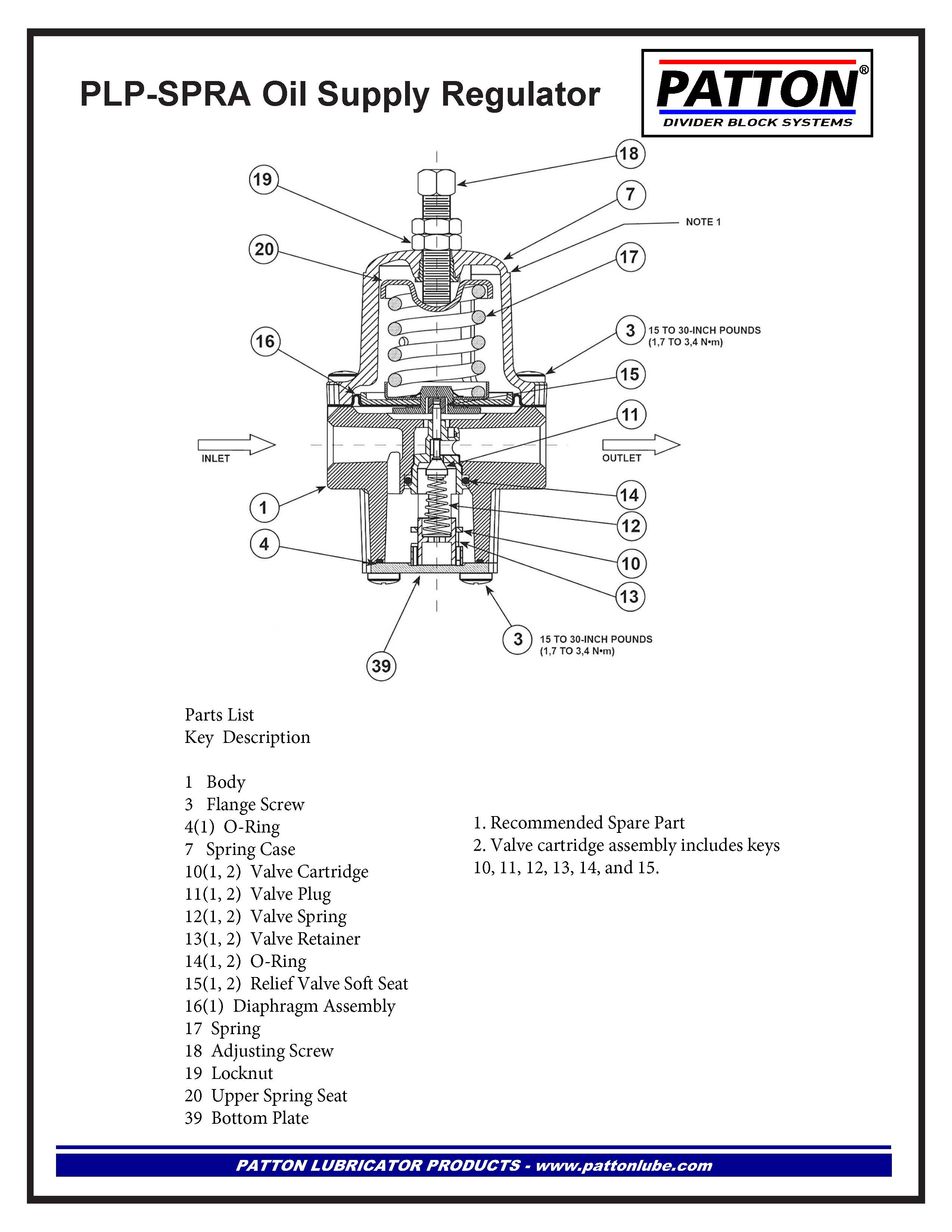

Oil Pressure Regulator

oil Pressure Regulator

PLP-SPRA OIL Supply Pressure Regulator

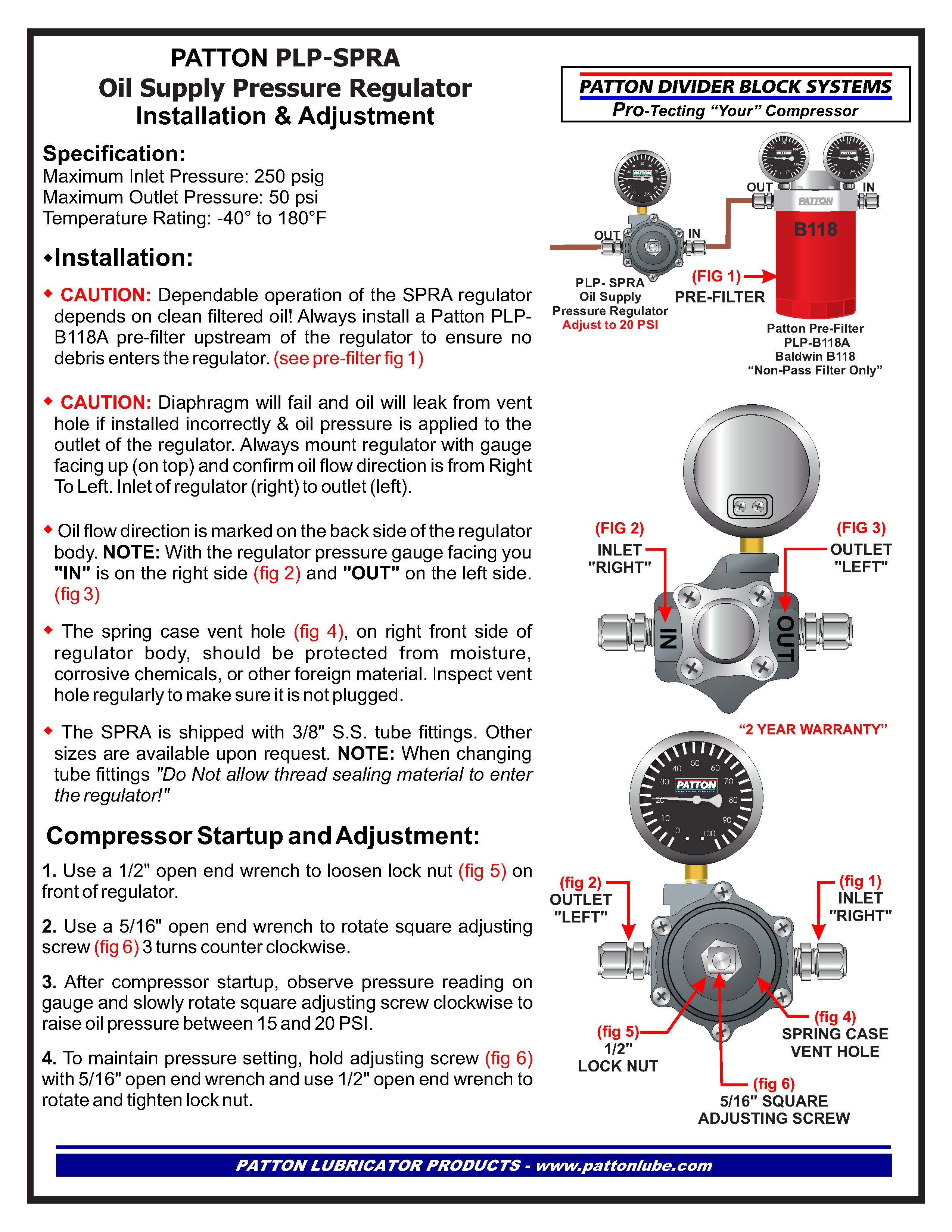

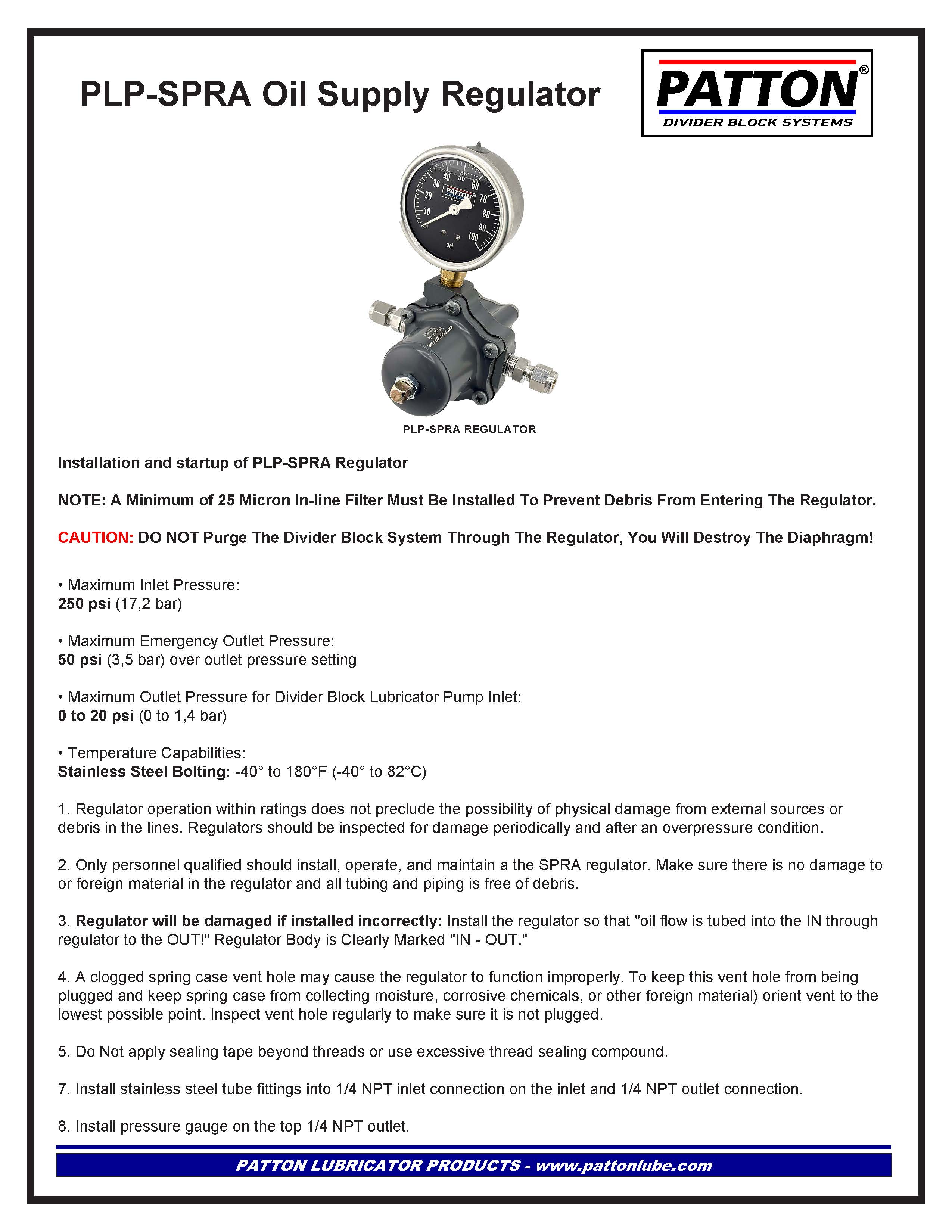

Regulating the oil supply pressure to 20 PSI or below, will not only reduce having to replace lube pumps due to by-passing oil into the lube box, but also allows the divider block to cycle more consistently. (Full PDF)

Oil Supply Regulator Brochure (click to expand or contract)

Oil Supply Regulator Installation Brochure (click to expand or contract)

Oil Supply Regulator Installation Brochure (click to expand or contract)

Oil Supply Regulator Installation Brochure (click to expand or contract)

Oil Supply Regulator Installation Brochure (click to expand or contract)

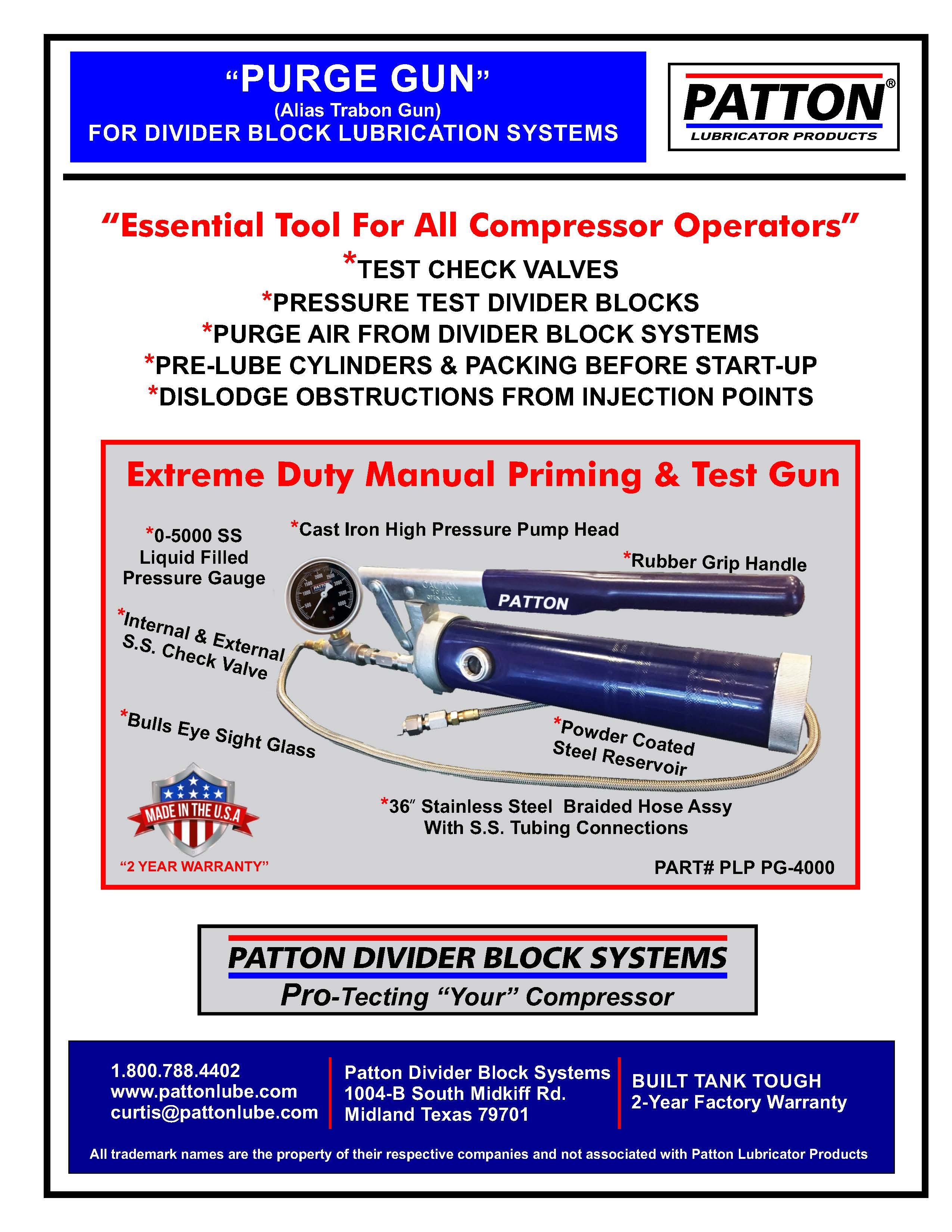

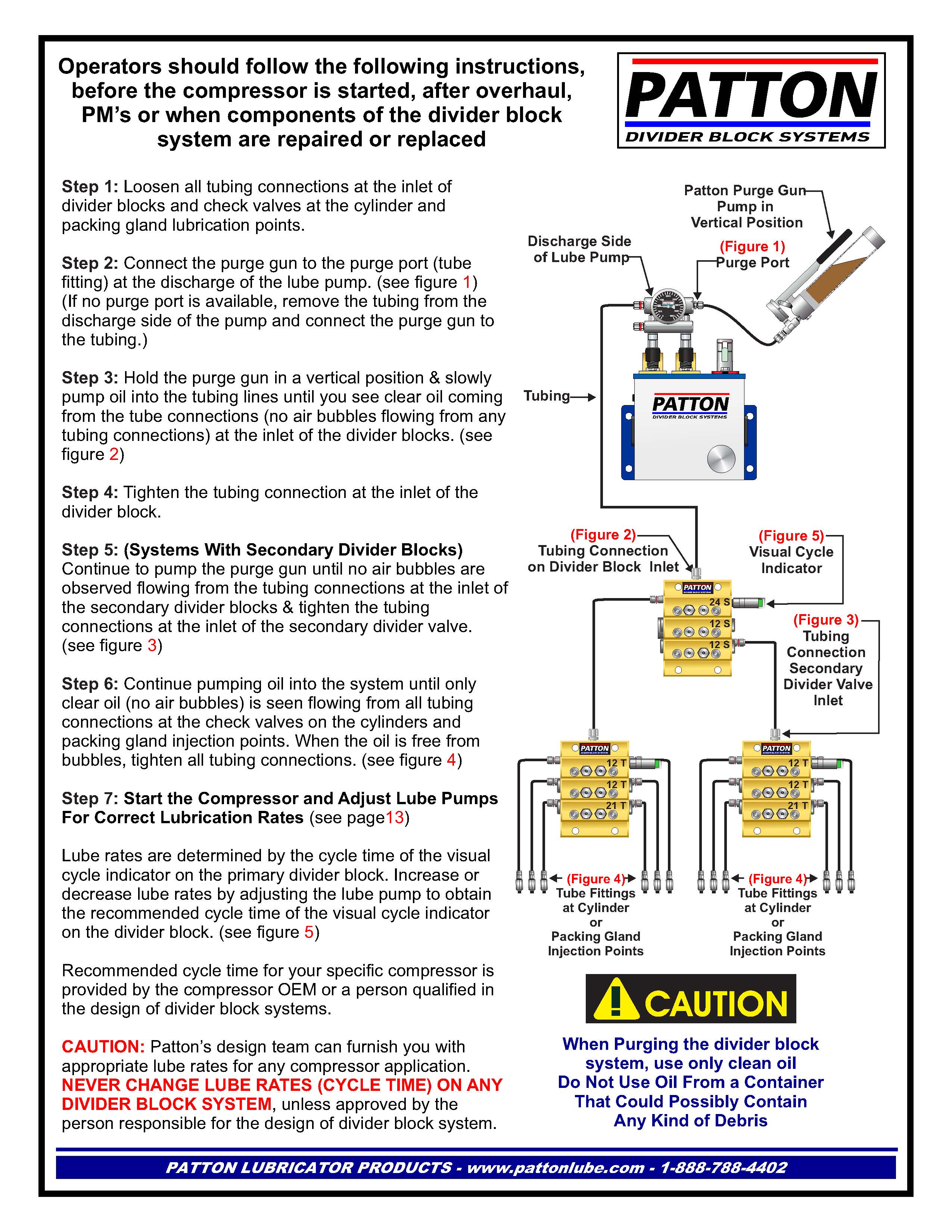

Purge Gun

Patton Purge Gun

Essential Tool For All Compressor Operators

Test Check Valves

Pressure Test Divider Blocks

Purge Air from Divider Block Systems

Pre-Lube Cylinders and Packing before Start-Up

Dislodge Obstructions from Injection Points

Purge Gun Brochure (click to expand or contract)

Purge Gun Use Brochure (click to expand or contract)